All stainless steel flanged butterfly valve

Keywords:

Included in the category:

Product Description

Analysis of valve plates

|

Part Name |

Material Name |

Adapt size |

PH value |

Chlorine content (ppm) |

Applicable temperature |

Advantages of material |

Applied Environment |

|

Butterfly plate |

SAF2507 Super double steel, S3 surface quality |

DN40 ~ 1200 |

≥ 3,0 |

<30,000 |

<35~150 ℃ |

Extremely wear resistance, corrosion resistance, Habits with high flow rate |

Limestone solution Gypsum suspension Washing slurry Gipsum suspension Craft water, waste water, etc. D. |

|

DIN1.4529 Super Double Stainless Steel |

≥ 5,0 |

<5,000 |

|||||

|

C276 Corrosion Resistant Solid Nickel Based Surface S3 Quality |

≥ 2,5 |

<50,000 |

|||||

|

Хостал Гур |

|||||||

|

CF3M Ultra-low Carbon Stainless Steel |

≥ 5,0 |

<5,000 |

Corrosion resistance |

Craft water, waste water, etc. D. |

Valve seat analysis

|

Part Name |

Material Name |

Adapt size |

PH value |

Chlorine content |

Applicable temperature |

Advantages of material |

Applied Environment |

|

Valve seat (valve lining) |

CSM elastic glue |

DN40 ~ 1200 |

≥ 0 |

<150,000 |

≤ 35 ~ 150 ℃ |

Resistance to abrasion and corrosion |

Limestone suspension, gypsum suspension Pā commonly referred to as a sleeper, Craft water, waste water, etc. D. |

|

EPDN Socket EPDM |

≥ 2,5 |

Habits with high flow rate |

Metal valve material, non-metallic material, corrosion resistance and heat resistance

|

Material |

Applicable temperature (°C) |

Environment and applicability |

Features |

|||||||||||

|

Fresh water |

Sea Water |

Strong alkali |

Weakly alkali |

Strong acid |

Weakable acid |

Alcohol |

Air |

Steam |

Oil |

Edda |

||||

|

Seat Valve Seat |

NBR |

-23 ℃-93 ℃ |

A |

A |

B |

A |

D |

B |

With |

A |

D |

A |

B |

Oil resistant |

|

EPC |

-46 ℃-135 ℃ |

A |

A |

A |

A |

With |

A |

B |

A |

A |

With |

A |

Anti-aging |

|

|

HP |

-20 ℃-85 ℃ |

A |

A |

A |

A |

With |

B |

With |

A |

B |

B |

B |

High elasticity |

|

|

KR |

-29 ℃ ~ 99 ℃ |

A |

B |

A |

A |

D |

With |

With |

A |

D |

D |

B |

Resistance to abrasion and aging |

|

|

SI |

-55 ℃ ~ 180 ℃ |

A |

B |

D |

B |

D |

B |

B |

A |

A |

With |

With |

Resistance to high temperature |

|

|

FPM |

-23 ℃-200 ℃ |

A |

A |

With |

A |

With |

A |

With |

A |

A |

A |

A |

Anticorrosive, high temperature |

|

|

PTFE |

-20 ℃ ~ 180 ℃ |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

Anti-corrosion all chemical environments |

|

|

Valve plate |

Electroplated iron |

-30 ℃-350 ℃ |

B |

With |

D |

With |

D |

With |

A |

B |

B |

A |

With |

Heat Resistant |

|

Polyamide |

-30 ℃-100 ℃ |

A |

A |

A |

A |

D |

A |

With |

A |

D |

A |

A |

Anti-corrosion, anti-alkali |

|

|

PCR |

-30 ℃-140 ℃ |

A |

A |

A |

A |

A |

A |

A |

A |

With |

A |

A |

Anti-corrosion, acid-resistant |

|

|

PTFE |

-20 ℃-180 ℃ |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

Anti-corrosion, all chemical environments |

|

|

PFA |

-20 ℃ ~ 180 ℃ |

A |

A |

A |

A |

B |

A |

A |

A |

A |

A |

A |

Anticorrosive, high temperature |

|

|

Stainless Steel |

-252 ℃ ~ 316 ℃ |

A |

With |

With |

B |

With |

B |

A |

A |

A |

A |

A |

Anticorrosive, high temperature |

|

|

Aluminum Bronze |

-212 ℃ ~ 232 ℃ |

A |

With |

With |

With |

D |

With |

A |

A |

A |

A |

With |

Heat resistance, resistance to ordinary temperature |

|

|

Titan |

-196 ℃ ~ 550 ℃ |

A |

A |

A |

A |

With |

B |

A |

A |

A |

A |

B |

Anticorrosive, high temperature |

|

Note: A is very suitable, B is suitable, C is limited use, D is not suitable.

Use

The worm gear driven flange butterfly valve produced by the company is widely used in nominal pressure ≤PN1.6MPa, suitable for temperature ≤200℃ of petroleum, chemical industry, food, pharmaceutical metallurgy, shipbuilding, paper, industrial environmental protection, water supply and drainage, high-rise building pipelines. It can be used for opening and closing or regulating medium flow in a variety of corrosive and non-corrosive gas, liquid, fluid and solid powder pipelines and containers.

Performance specification

| Numerical diameter DN(mm) | DN50 ~ 1000 |

| Ng pass PN(MPa) | 1,0-1,6 |

| Applicable temperature °C | -23 ~ 121 |

| Applicable media | Fresh water, waste water, sea water, gases, etc. D. |

Main components and materials

|

Part Name |

Material Name |

|

Valve body |

Gray Cast Iron, Carpet Cast Iron, Stainless Steel |

|

Valve plate |

Cast iron, stainless steel, aluminum alloy |

|

Вал клапана |

Carbon steel, stainless steel |

|

Valve Seat |

Rubber |

|

Seal |

O ring |

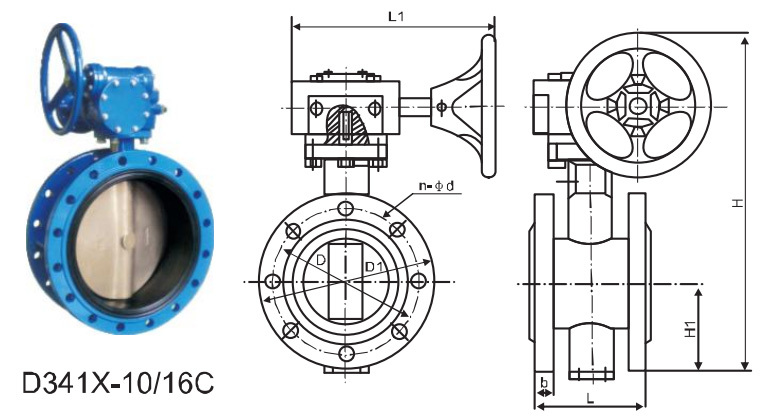

Main Size Chart

|

DN |

L |

L1 |

D |

D1 |

H |

H1 |

B |

N-Φd |

|||

|

Mm |

Deum |

PN1.0MPa |

PN1.6 MP |

PN1.0MPa |

PN1.6 MP |

||||||

|

50 |

2 inch |

108 |

180 |

125 |

125 |

150 |

326 |

83 |

20 |

4-Φ18 |

4-Φ18 |

|

65 |

21/2 inches |

112 |

180 |

145 |

145 |

165 |

344 |

93 |

20 |

4-Φ18 |

4-Φ18 |

|

80 |

3 inches |

114 |

180 |

160 |

160 |

200 |

363 |

100 |

22 |

4-Φ18 |

8-Φ18 |

|

100 |

4 inches |

127 |

180 |

180 |

180 |

220 |

396 |

114 |

22 |

8-Φ18 |

8-Φ18 |

|

125 |

5 inch |

140 |

180 |

210 |

210 |

250 |

421 |

125 |

24 |

8-Φ18 |

8-Φ18 |

|

150 |

6 inch |

140 |

180 |

240 |

240 |

280 |

453 |

143 |

24 |

8-Φ23 |

8-Φ23 |

|

200 |

8 inch |

152 |

270 |

295 |

295 |

335 |

578 |

170 |

26 |

8-Φ23 |

12-Φ23 |

|

250 |

10 inch |

165 |

270 |

350 |

355 |

405 |

638 |

198 |

26 |

12-Φ23 |

12-Φ28 |

|

300 |

12 inch |

178 |

380 |

400 |

410 |

455 |

731 |

223 |

32 |

12-Φ23 |

12-Φ28 |

|

350 |

14 inch |

190 |

380 |

460 |

470 |

525 |

783 |

270 |

36 |

16-Φ23 |

16-Φ28 |

|

400 |

16 inch |

216 |

450 |

515 |

525 |

580 |

888 |

300 |

38 |

16-Φ28 |

16-Φ31 |

|

450 |

18 inch |

222 |

480 |

565 |

585 |

640 |

958 |

340 |

40 |

20-Φ28 |

20-Φ31 |

|

500 |

20 inch |

229 |

480 |

620 |

650 |

705 |

1005 |

355 |

42 |

20-Φ28 |

20-Φ34 |

|

600 |

24 inches |

267 |

480 |

725 |

770 |

825 |

1128 |

410 |

48 |

20-Φ30 |

20-Φ36 |

|

700 |

28 inch |

292 |

640 |

840 |

840 |

920 |

1476 |

478 |

53 |

24-Φ30 |

24-Φ36 |

|

800 |

32 inches |

318 |

640 |

950 |

950 |

1020 |

1533 |

525 |

58 |

24-Φ33 |

24-Φ39 |

|

900 |

36 inch |

330 |

750 |

1050 |

1050 |

1120 |

1655 |

585 |

65 |

28-Φ33 |

28-Φ39 |

|

1000 |

40 inch |

410 |

850 |

1160 |

1170 |

1340 |

1765 |

640 |

76 |

28-Φ36 |

28-Φ42 |

|

1200 |

48 inch |

470 |

850 |

1380 |

1390 |

1560 |

1995 |

755 |

85 |

32-Φ39 |

32-Φ48 |

|

1400 |

56 inch |

530 |

1000 |

1590 |

1590 |

1760 |

2310 |

910 |

103 |

36-Φ42 |

36-Φ48 |

|

1600 |

64 inches |

600 |

1000 |

1820 |

1820 |

1970 |

2595 |

1030 |

123 |

40-Φ48 |

40-Φ56 |

|

1800 |

72 inches |

697 |

1100 |

2020 |

2020 |

2180 |

2810 |

1140 |

135 |

44-Φ48 |

44-Φ56 |

|

2000 |

80 inch |

760 |

1100 |

2230 |

2230 |

2345 |

3100 |

1250 |

145 |

48-Φ48 |

48-Φ62 |

Products Message

We will contact you within one working day. Please pay attention to your email.