American standard gate valve

Keywords:

Included in the category:

Product Description

Overview

Z41H-150LB American standard cast steel gate valve has three types of bonnet design: the first is a bolt type bonnet, according to this design of the valve, the valve body and bonnet with a bolt and nut connection, winding gasket (304 clip flexible graphite manufacturing). Customers have special requirements can also be used when the metal ring connection. The second design form is welded bonnet, according to this design form of the valve, the valve body and the bonnet threaded connection, full welding seal. The joint penetration connection can also be used when the customer has special requirements. The third is the pressure self-tightening valve cover, according to this design form of the design of the valve, the valve body and the valve cover with threaded connection, internal pressure from the sealing ring seal, flange end valve to adapt to the gate valve, globe valve, lift check valve and swing check valve and ball valve.

Product Features

The product design and manufacture meet the requirements of foreign advanced standards, reliable sealing and excellent performance.

The structure design is compact and reasonable, beautiful shape.

③ Using wedge type elastic gate structure, medium and large diameter rolling bearing, easy opening and closing.

The valve body material varieties, packing, gasket according to the actual conditions or user requirements reasonable selection, can be applied to a variety of pressure, temperature and medium conditions.

⑤ Adopt a variety of domestic and foreign piping flange standards and flange sealing surface types to meet various engineering needs and user requirements.

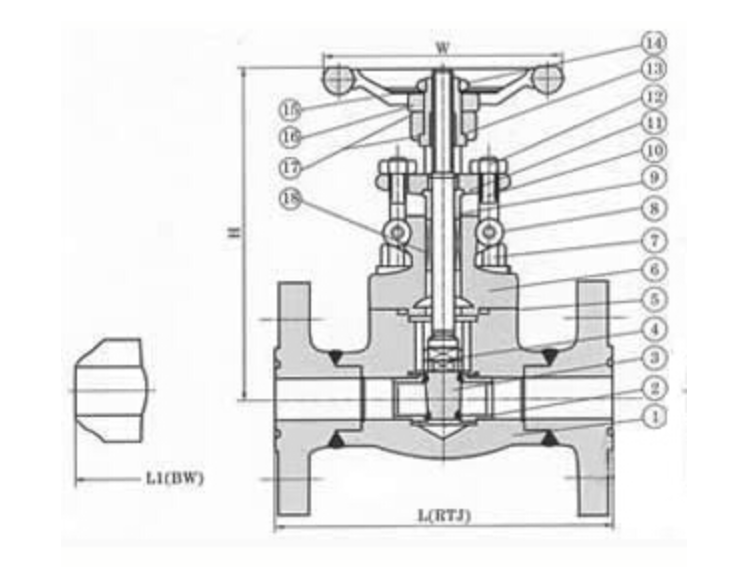

Structure Diagram

Performance Specification

Nominal pressure (LB) | Strength test | Water seal test | Gas seal test | |||

MPa | Lbf/in2 | Mpa | Lbf/in2 | MPa | Lbf/in2 | |

150 | 3.1 | 450 | 2.2 | 315 | 0. 5~0.7 | 60~100 |

Material of product parts

Valve body, Bonnet, Ram | WCB | ZG1Cr18Ni9T i | CF8(304) | CF3(304L) | ZG1Cr18Ni1 2Mo2Ti | CF8M(316) |

Sealing surface | Cr13 or hard quality alloy | Ontology (W) or Cemented Carbide (Y) |

|

|

|

|

Stem and Internals | 2Cr13 | 1Cr18Ni9Ti | 0Cr19Ni9 (304) | 00Cr19Ni1 1(304L) | 1Cr18Ni12M o2Ti | 0Cr17Ni12Mo 2(316) |

Packing | flexible graphite |

|

|

|

|

|

Gasket | Stainless steel winding Winding gasket |

|

|

|

|

|

Applicable medium Quality | water, steam, Oil products, etc. | Nitric acid and other corrosion sexual medium |

| strong oxidizing Medium | Acetic acid and other corrosion sexual medium |

|

Applicable temperature Degree | -29~425 C | -40~500 ℃ |

|

|

|

|

Product shape and connection dimensions

kg | DN | Dimensions (mm) | Weight (kg) | ||||||||||||||

d |

| LJ |

| D1 | D2 | b | z-φd | W | H ON | ||||||||

mm | in | ZA40 | ZA540 | ZA940 | ZA40 | ZA540 | ZA940 | ||||||||||

Class | 25 | 1 | 25 | 127 | 140 | 108 | 79.5 | 51 | 11.5 | 4-15 | 120 | 200 |

| 330 | 7 |

| 31 |

32 | 11/4 | 32 | 140 | 153 | 117 | 89 | 64 | 13 | 4-15 | 140 | 235 |

| 375 | 9 |

| 33 | |

40 | 1/2 | 38 | 165 | 178 | 127 | 98.5 | 73 | 14.5 | 4-15 | 180 | 285 |

| 435 | 13 |

| 38 | |

50 | 2 | 51 | 178 | 191 | 152 | 120.5 | 92 | 16 | 4-19 | 180 | 390 |

| 610 | 19 |

| 45 | |

65 | 21/2 | 64 | 190 | 203 | 178 | 139.5 | 105 | 17.5 | 4-19 | 200 | 435 |

| 655 | 24 |

| 65 | |

80 | 3 | 76 | 203 | 216 | 190 | 152.5 | 127 | 19.5 | 4-19 | 200 | 515 |

| 680 | 36 |

| 85 | |

00 | 4 | 102 | 229 | 242 | 229 | 190.5 | 157 | 24 | 8-19 | 250 | 595 |

| 750 | 46 |

| 95 | |

125 | 5 | 127 | 254 | 267 | 254 | 216 | 186 | 24 | 8-22 | 250 | 725 |

| 820 | 65 |

| 115 | |

50 | 6 | 152 | 267 | 280 | 279 | 241.5 | 216 | 25.5 | 8-22 | 300 | 780 |

| 900 | 82 |

| 135 | |

200 | 8 | 203 | 292 | 305 | 343 | 298.5 | 270 | 29 | 8-22 | 300 | 975 | 1010 | 1060 | 126 | 155 | 182 | |

250 | 10 | 254 | 330 | 343 | 406 | 362 | 324 | 30.5 | 12-25 | 350 | 1150 | 1190 | 1250 | 178 | 213 | 230 | |

300 | 12 | 305 | 356 | 369 | 483 | 432 | 381 | 32 | 12-25 | 400 | 1380 | 1420 | 500 | 258 | 290 | 320 | |

350 | 14 | 337 | 381 | 394 | 533 | 476 | 413 | 35 | 12-29 | 400 | 1540 | 1580 | 1750 | 385 | 430 | 470 | |

400 | 16 | 387 | 406 | 419 | 597 | 540 | 470 | 37 | 16-29 | 500 | 1740 | 780 | 950 | 485 | 540 | 610 | |

450 | 18 | 438 | 432 | 445 | 635 | 578 | 533 | 40 | 16-32 | 500 | 1950 | 1990 | 2150 | 580 | 640 | 710 | |

500 | 20 | 489 | 457 | 470 | 699 | 635 | 584 | 43 | 20-32 | 600 | 2180 | 2220 | 2350 | 680 | 740 | 820 | |

600 | 24 | 591 | 508 | 521 | 813 | 749.5 | 692 | 48 | 20-32 | 650 | 2560 | 2600 | 2710 | 940 | 1000 | 1080 | |

Products Message

We will contact you within one working day. Please pay attention to your email.