Lug against clamp butterfly valve

Keywords:

Included in the category:

Product Description

Analysis of valve plates

|

Part Name |

Material Name |

Adapt size |

PH value |

Chlorine content (ppm) |

Applicable temperature |

Advantages of material |

Applied Environment |

|

Butterfly plate |

SAF2507 Super double steel, S3 surface quality |

DN40 ~ 1200 |

≥ 3,0 |

<30,000 |

<35~150 ℃ |

Extremely wear resistance, corrosion resistance, Habits with high flow rate |

Limestone solution Gypsum suspension Washing slurry Gipsum suspension Craft water, waste water, etc. D. |

|

DIN1.4529 Super Double Stainless Steel |

≥ 5,0 |

<5,000 |

|||||

|

C276 Corrosion Resistant Solid Nickel Based Surface S3 Quality |

≥ 2,5 |

<50,000 |

|||||

|

Хостал Гур |

|||||||

|

CF3M Ultra-low Carbon Stainless Steel |

≥ 5,0 |

<5,000 |

Corrosion resistance |

Craft water, waste water, etc. D. |

Valve seat analysis

|

Part Name |

Material Name |

Adapt size |

PH value |

Chlorine content |

Applicable temperature |

Advantages of material |

Applied Environment |

|

Valve seat (valve lining) |

CSM elastic glue |

DN40 ~ 1200 |

≥ 0 |

<150,000 |

≤ 35 ~ 150 ℃ |

Resistance to abrasion and corrosion |

Limestone suspension, gypsum suspension Pā commonly referred to as a sleeper, Craft water, waste water, etc. D. |

|

EPDN Socket EPDM |

≥ 2,5 |

Habits with high flow rate |

Metal valve material, non-metallic material, corrosion resistance and heat resistance

|

Material |

Applicable temperature (°C) |

Environment and applicability |

Features |

|||||||||||

|

Fresh water |

Sea Water |

Strong alkali |

Weakly alkali |

Strong acid |

Weakable acid |

Alcohol |

Air |

Steam |

Oil |

Edda |

||||

|

Seat Valve Seat |

NBR |

-23 ℃-93 ℃ |

A |

A |

B |

A |

D |

B |

With |

A |

D |

A |

B |

Oil resistant |

|

EPC |

-46 ℃-135 ℃ |

A |

A |

A |

A |

With |

A |

B |

A |

A |

With |

A |

Anti-aging |

|

|

HP |

-20 ℃-85 ℃ |

A |

A |

A |

A |

With |

B |

With |

A |

B |

B |

B |

High elasticity |

|

|

KR |

-29 ℃ ~ 99 ℃ |

A |

B |

A |

A |

D |

With |

With |

A |

D |

D |

B |

Resistance to abrasion and aging |

|

|

SI |

-55 ℃ ~ 180 ℃ |

A |

B |

D |

B |

D |

B |

B |

A |

A |

With |

With |

Resistance to high temperature |

|

|

FPM |

-23 ℃-200 ℃ |

A |

A |

With |

A |

With |

A |

With |

A |

A |

A |

A |

Anticorrosive, high temperature |

|

|

PTFE |

-20 ℃ ~ 180 ℃ |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

Anti-corrosion all chemical environments |

|

|

Valve plate |

Electroplated iron |

-30 ℃-350 ℃ |

B |

With |

D |

With |

D |

With |

A |

B |

B |

A |

With |

Heat Resistant |

|

Polyamide |

-30 ℃-100 ℃ |

A |

A |

A |

A |

D |

A |

With |

A |

D |

A |

A |

Anti-corrosion, anti-alkali |

|

|

PCR |

-30 ℃-140 ℃ |

A |

A |

A |

A |

A |

A |

A |

A |

With |

A |

A |

Anti-corrosion, acid-resistant |

|

|

PTFE |

-20 ℃-180 ℃ |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

Anti-corrosion, all chemical environments |

|

|

PFA |

-20 ℃ ~ 180 ℃ |

A |

A |

A |

A |

B |

A |

A |

A |

A |

A |

A |

Anticorrosive, high temperature |

|

|

Stainless Steel |

-252 ℃ ~ 316 ℃ |

A |

With |

With |

B |

With |

B |

A |

A |

A |

A |

A |

Anticorrosive, high temperature |

|

|

Aluminum Bronze |

-212 ℃ ~ 232 ℃ |

A |

With |

With |

With |

D |

With |

A |

A |

A |

A |

With |

Heat resistance, resistance to ordinary temperature |

|

|

Titan |

-196 ℃ ~ 550 ℃ |

A |

A |

A |

A |

With |

B |

A |

A |

A |

A |

B |

Anticorrosive, high temperature |

|

Note: A is very suitable, B is suitable, C is limited use, D is not suitable.

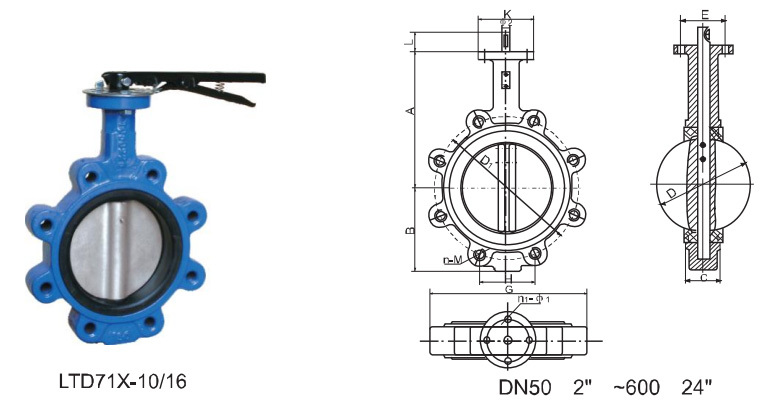

Butterfly Valve type "LT" Main dimensions and weight

|

DN |

A |

B |

With |

D |

L |

H |

D1 |

N-Φ |

К |

E |

N1-Φ1 |

Φ2 |

D |

Wes Weight(kg) |

|

|

Mm |

Deum |

||||||||||||||

|

50 |

2 inch |

161 |

80 |

42 |

52,9 |

32 |

88,38 |

125 |

4-M16 |

77 |

57,15 |

4-6,7 |

12,6 |

118 |

3,8 |

|

65 |

2.5 inches |

175 |

89 |

44,7 |

64,5 |

32 |

102,54 |

145 |

4-M16 |

77 |

57,15 |

4-6,7 |

12,6 |

137 |

4,2 |

|

80 |

3 inches |

181 |

95 |

45,2 |

78,8 |

32 |

61,23 |

160 |

8-M16 |

77 |

57,15 |

4-6,7 |

12,6 |

178 |

4,7 |

|

100 |

4 inches |

200 |

114 |

52,1 |

104 |

32 |

68,88 |

180 |

8-M16 |

92 |

69,85 |

4-10,3 |

15,77 |

206 |

9,0 |

|

125 |

5 inch |

213 |

127 |

54,4 |

123,3 |

32 |

80,36 |

210 |

8-M16 |

92 |

69,85 |

4-10,3 |

18,92 |

238 |

10,9 |

|

150 |

6 inch |

226 |

139 |

55,8 |

155,6 |

32 |

91,84 |

240 |

8-M20 |

92 |

69,85 |

4-10,3 |

18,92 |

266 |

14,2 |

|

200 |

8 inch |

260 |

175 |

60,6 |

202,5 |

45 |

112,89 76,35 |

295 |

8-M20 12-M24 |

115 |

88,9 |

4-14,3 |

22,1 |

329 |

18,2 |

|

250 |

10 inch |

292 |

203 |

65,6 |

250,5 |

45 |

90,59 91,88 |

350 355 |

12-M20 12-M24 |

115 |

88,9 |

4-14,3 |

28,45 |

393 |

26,8 |

|

300 |

12 inch |

337 |

242 |

76,9 |

301,6 |

45 |

103,52 106,12 |

400 410 |

12-M20 12-M24 |

140 |

107,95 |

4-14,3 |

31,6 |

462 |

40 |

|

350 |

14 inch |

368 |

267 |

76,5 |

333,3 |

45 |

89,74 91,69 |

460 470 |

16-M20 16-M24 |

140 |

107,95 |

4-14,3 |

31,6 |

515 |

56 |

|

400 |

16' |

400 |

309 |

86,5 |

389,6 |

51,2 72 |

100,48 102,42 |

515 525 |

16-M24 16-M27 |

197 |

158,75 |

4-20,6 |

33,15 |

579 |

96 |

|

450 |

18 inch |

422 |

328 |

105,6 |

440,51 |

51,2 72 |

88,38 91,51 |

565 585 |

20-M24 20-M27 |

197 |

158,75 |

4-20,6 |

38 |

627 |

122 |

|

500 |

20 inch |

480 |

361 |

131,8 |

491,6 |

64,2 82 |

96,99 101,68 |

620 650 |

20-M24 20-M30 |

197 |

156,25 |

4-20,6 |

41,15 |

696 |

202 |

|

600 |

24 |

562 |

459 |

152 |

592,5 |

70,2 82 |

113,42 120,46 |

725 770 |

20-M27 20-M33 |

276 |

215,9 |

4-22,2 |

50,65 |

821 |

270 |

Note

DN50 2 "~ Type 600 Butterfly Valve 24" LT "is suitable for two PN1.0/PN1.6 MPa pressure stages, each of which has two sizes, respectively, denoting two sizes of the PN1.0PN/1.6MPa pressure stage connection. The pipe flange joint ruler connected to the valve refers to the size table of the flange connection. The upper throttle flange can be used for manual, worm, electric, pneumatic and other transmission devices.

The structure, characteristics and material of the "LT" type throttle are the same as that of "A". The difference is that type "A" can be connected between two tube flanges via a two-headed hairpin or an elongated hex bolt. In addition to the connection between the two pipes with two conventional hex bolts, the "LI" type can also be installed at the end of the pipe, that is, in the form of a single clamp, as a drainage valve, but the end of the pipe must be specified in the order contract.

● The above two forms are specified by the user in the order contract.

● Flange connection size complies with G4216 DIN2501 BS4504 BS10-E JISB2220 AS2129 ANSIB16.1 etc. D. The user must specify in the contract.

Products Message

We will contact you within one working day. Please pay attention to your email.