Globe valve

I-flange type, self-sealing multi-structure type meets the user's requirements.

Keywords:

Included in the category:

Product Description

Features

1. Multi-flange type, self-sealing multi-structure type meets user requirements.

2. can be installed anywhere in the pipeline for quick opening and closing, wear and corrosion resistance.

3. Stainless steel globe valve is suitable for pipes on every corrosive environment with good corrosion resistance and sufficient strength.

4. Alloy steel controversial valve is suitable for high temperature steam and oil pipes with high temperature resistance characteristics.

Performance specification

| Non-pressure PN (MIP) |

Test pressure (MPa) | ||||||||||||

| Housing | Seal | Top seals | |||||||||||

| 1,6 | 2,4 | 1,8 | 1,8 | ||||||||||

| 2,5 | 3,8 | 2,8 | 2,8 | ||||||||||

| 4,0 | 6,0 | 4,4 | 4,4 | ||||||||||

Scope of application

| Product Type | Applicable media | Applicable temperature °C | |||||||||||

| J41 H/Y-C J941 H/Y-C |

Water, steam, oil products | ≤ 425 | |||||||||||

| ≤ 450 | |||||||||||||

| Type J41W-P Type J941W-P |

Nitric acids | ≤ 200 | |||||||||||

| Type J41W-R | Acetic acid | ≤ 200 | |||||||||||

| Type J41Y-I | Water, steam, oil products | ≤ 550 | |||||||||||

Main components and materials

| Product Type | Part Name | ||||||||||||||||||||||

| Valve Body, Valve Cover | Valve stem | Valve | Sealing Cover | Valve Rod Nut | Filler | Fastening | Hand Wheel | ||||||||||||||||

| J41 H/Y-C J941 H/Y -C |

25 AD | Stainless Steel Chrome | 2Cr13 25 |

H: Stainless Steel Y: Solid Cobalt Based Alloy Steel |

Aluminum Copper | Flexible Graphite | High quality carbon steel | Forged cast iron | |||||||||||||||

| Type J41W-P Type J941W-P |

Chrome-nickel-titanium steel | Chrome-nickel-titanium steel | Chrome-nickel-titanium steel | Chrome-nickel-titanium steel | Aluminum Copper | Flexible Graphite | Stainless Steel | Forged cast iron | |||||||||||||||

| Type J41W-R | Chrome-nickel-molybdenum-titanium steel | Chrome-nickel-molybdenum-titanium steel | Chrome-nickel-molybdenum-titanium steel | Chrome-nickel-molybdenum-titanium steel | Aluminum Copper | Flexible Graphite | Stainless Steel | Forged cast iron | |||||||||||||||

| Type J41Y-I Type J941Y-I |

Chromomolybdenum steel | Chromomolybdenum steel | Alloy Steel | Cobalt based rigid alloy steel | Aluminum Copper | Flexible Graphite | Alloy Steel | Forged cast iron | |||||||||||||||

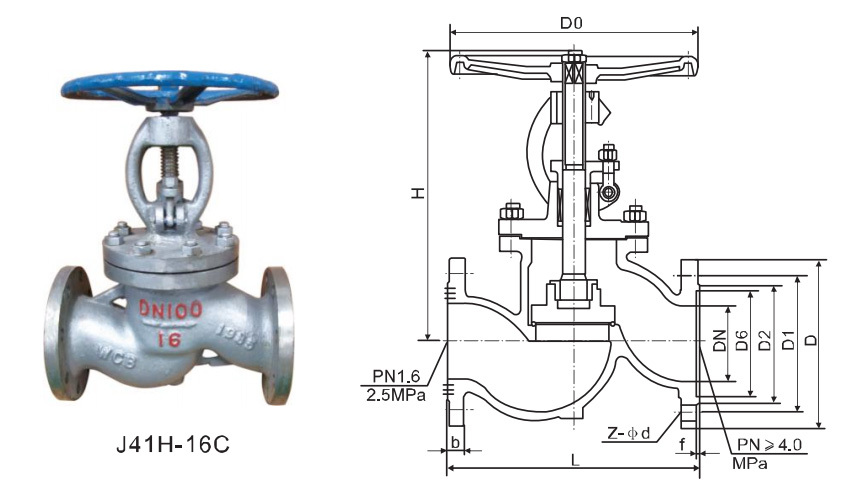

Main shape and connection size and weight

| PN (MP) |

DN (Mm) |

L | D | D1 | Д 2 | Д 6 | B | F | F2 | N-Φd | H | D0 | Wes (Kg) | ||||||||||

| 1,6 | 10 | 130 | 90 | 60 | 40 | 14 | 2 | 4-Φ14 | 198 | 120 | 4,7 | ||||||||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | 218 | 120 | 5,2 | |||||||||||||

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-Φ14 | 258 | 140 | 7,1 | |||||||||||||

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-Φ14 | 275 | 160 | 7,4 | |||||||||||||

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-Φ18 | 280 | 180 | 8,5 | |||||||||||||

| 40 | 200 | 145 | 110 | 85 | 18 | 3 | 4-Φ18 | 330 | 200 | 12,5 | |||||||||||||

| 50 | 230 | 160 | 125 | 100 | 18 | 3 | 4-Φ18 | 350 | 240 | 14 | |||||||||||||

| 65 | 290 | 180 | 145 | 120 | 18 | 3 | 4-Φ18 | 400 | 280 | 22,5 | |||||||||||||

| 80 | 310 | 195 | 160 | 135 | 20 | 3 | 8-Φ18 | 355 | 280 | 29 | |||||||||||||

| 100 | 350 | 215 | 180 | 155 | 22 | 3 | 8-Φ18 | 415 | 320 | 32,5 | |||||||||||||

| 125 | 400 | 245 | 210 | 185 | 24 | 3 | 8-Φ18 | 460 | 360 | 80 | |||||||||||||

| 150 | 480 | 280 | 240 | 210 | 24 | 3 | 8-Φ23 | 510 | 400 | 93,5 | |||||||||||||

| 200 | 600 | 335 | 295 | 265 | 26 | 3 | 12-Φ23 | 710 | 400 | 180 | |||||||||||||

| 250 | 650 | 405 | 355 | 320 | 30 | 3 | 12-Φ23 | 786 | 450 | 440 | |||||||||||||

| 300 | 750 | 460 | 410 | 375 | 30 | 3 | 12-Φ23 | 925 | 500 | 648 | |||||||||||||

| 2,5 | 10 | 130 | 90 | 60 | 40 | 16 | 2 | 4-Φ14 | 198 | 120 | 4,9 | ||||||||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | 218 | 120 | 5,4 | |||||||||||||

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-Φ14 | 258 | 140 | 7 | |||||||||||||

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-Φ14 | 275 | 160 | 7,4 | |||||||||||||

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-Φ18 | 280 | 180 | 8,5 | |||||||||||||

| 40 | 200 | 145 | 110 | 85 | 18 | 2 | 4-Φ18 | 330 | 200 | 12,5 | |||||||||||||

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-Φ18 | 350 | 240 | 16 | |||||||||||||

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-Φ18 | 400 | 280 | 25 | |||||||||||||

| 80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-Φ18 | 355 | 280 | 30 | |||||||||||||

| 100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-Φ23 | 415 | 320 | 34,5 | |||||||||||||

| 125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-Φ25 | 460 | 360 | 89 | |||||||||||||

| 150 | 480 | 300 | 250 | 218 | 30 | 3 | 8-Φ25 | 510 | 400 | 98 | |||||||||||||

| 200 | 600 | 360 | 310 | 278 | 34 | 3 | 12-Φ25 | 710 | 400 | 180 | |||||||||||||

| 250 | 650 | 425 | 370 | 332 | 36 | 3 | 12-Φ30 | 786 | 450 | 446 | |||||||||||||

| 300 | 750 | 485 | 430 | 390 | 40 | 4 | 12-Φ30 | 952 | 500 | 654 | |||||||||||||

| 4,0 | 10 | 130 | 90 | 60 | 40 | 35 | 16 | 2 | 4 | 4-Φ14 | 198 | 120 | 4,9 | ||||||||||

| 15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-Φ14 | 233 | 120 | 5,7 | |||||||||||

| 20 | 150 | 105 | 75 | 55 | 51 | 16 | 2 | 4 | 4-Φ14 | 275 | 140 | 7 | |||||||||||

| 25 | 160 | 115 | 85 | 65 | 58 | 16 | 2 | 4 | 4-Φ14 | 285 | 160 | 8,8 | |||||||||||

| 32 | 180 | 135 | 100 | 78 | 66 | 18 | 2 | 4 | 4-Φ18 | 302 | 180 | 11,8 | |||||||||||

| 40 | 200 | 145 | 110 | 85 | 76 | 18 | 3 | 4 | 4-Φ18 | 355 | 200 | 16,5 | |||||||||||

| 50 | 230 | 160 | 125 | 100 | 88 | 20 | 3 | 4 | 4-Φ18 | 373 | 240 | 24 | |||||||||||

| 65 | 290 | 180 | 145 | 120 | 110 | 22 | 3 | 4 | 8-Φ18 | 408 | 280 | 33 | |||||||||||

| 80 | 310 | 195 | 160 | 135 | 121 | 22 | 3 | 4 | 8-Φ18 | 436 | 320 | 44 | |||||||||||

| 100 | 350 | 230 | 190 | 160 | 150 | 24 | 3 | 4,5 | 8-Φ23 | 480 | 360 | 60 | |||||||||||

| 125 | 400 | 270 | 220 | 188 | 176 | 28 | 3 | 4,5 | 8-Φ25 | 558 | 400 | 89 | |||||||||||

| 150 | 480 | 300 | 250 | 218 | 204 | 30 | 3 | 4,5 | 8-Φ25 | 611 | 400 | 98 | |||||||||||

| 200 | 600 | 375 | 320 | 282 | 260 | 38 | 3 | 4,5 | 12-Φ30 | 720 | 400 | 190 | |||||||||||

Products Message

We will contact you within one working day. Please pay attention to your email.