Electric globe valve

Keywords:

Included in the category:

Product Description

Features

The electric gate valve compared to the traditional manual globe valve has the following features:

(1) Automatic control:

The electric gate valve can carry out remote control without manual control.

Simply send instructions through the electrical control system to achieve remote switching or valve opening adjustment.

(2) Accurate control:

The electric gate valve can accurately control the flow rate and pressure of the liquid according to the specified parameters, which increases the stability and reliability of the pipeline system.

(3) Quick response:

electric gate valves have a high response rate and can instantly complete switching, which is suitable for cases with high liquid flow requirements and high reaction rate.

(4) Programmability:

The electric gate valve can be automated with programming, high flexibility and high adaptability.

Working principle

The working principle of the electric gate valve mainly includes the following links:

(1) Прием сигнала:

The electric gate valve controls the opening and closing of the valve by receiving a signal from the electronic control system.

(2) Electric Actuator:

When a signal is received, the electric actuator of the electric gate valve converts the signal into force or torque, driving the opening or closing of the valve.

(3) Valve Control:

Electrical globe valve perform truncation or fluid adjustment through the valve design and control method.

Scope of application

electric gate valve has a wide range of applications in many fields:

(1) Industrial Scope:

electric gate valves can be used in piping systems of chemical, petroleum, pharmaceutical and other industries, to control the flow and pressure of fluid, to ensure the stability and safety of the production process.

(2) Construction Zone:

The electric gate valve plays a key role in the water supply and drainage systems of buildings and public facilities, it can regulate water flow as needed and keep the water supply running smoothly.

3) In the field of energy:

electric gate valves are often used in energy systems, such as the production of thermal energy and wind power, which can accurately control fluid supply and transmission and improve energy use.

(4) Metallurgy:

electric gate valves are used in the metallurgical industry to control liquids and gases at high temperatures and pressures, and play an important role in the smelting process.

Performance specification

| Non-pressure PN (MIP) |

Test pressure (MPa) | ||||||||||||

| Housing | Seal | Top seals | |||||||||||

| 1,6 | 2,4 | 1,8 | 1,8 | ||||||||||

| 2,5 | 3,8 | 2,8 | 2,8 | ||||||||||

| 4,0 | 6,0 | 4,4 | 4,4 | ||||||||||

Scope of application

| Product Type | Applicable media | Applicable temperature °C | |||||||||||

| J41 H/Y-C J941 H/Y-C |

Water, steam, oil products | ≤ 425 | |||||||||||

| ≤ 450 | |||||||||||||

| Type J41W-P Type J941W-P |

Nitric acids | ≤ 200 | |||||||||||

| Type J41W-R | Acetic acid | ≤ 200 | |||||||||||

| Type J41Y-I | Water, steam, oil products | ≤ 550 | |||||||||||

Main components and materials

| Product Type | Part Name | ||||||||||||||||||||||

| Valve Body, Valve Cover | Valve stem | Valve | Sealing Cover | Valve Rod Nut | Filler | Fastening | Hand Wheel | ||||||||||||||||

| J41 H/Y-C J941 H/Y -C |

25 AD | Stainless Steel Chrome | 2Cr13 25 |

H: Stainless Steel Y: Solid Cobalt Based Alloy Steel |

Aluminum Copper | Flexible Graphite | High quality carbon steel | Forged cast iron | |||||||||||||||

| Type J41W-P Type J941W-P |

Chrome-nickel-titanium steel | Chrome-nickel-titanium steel | Chrome-nickel-titanium steel | Chrome-nickel-titanium steel | Aluminum Copper | Flexible Graphite | Stainless Steel | Forged cast iron | |||||||||||||||

| Type J41W-R | Chrome-nickel-molybdenum-titanium steel | Chrome-nickel-molybdenum-titanium steel | Chrome-nickel-molybdenum-titanium steel | Chrome-nickel-molybdenum-titanium steel | Aluminum Copper | Flexible Graphite | Stainless Steel | Forged cast iron | |||||||||||||||

| Type J41Y-I Type J941Y-I |

Chromomolybdenum steel | Chromomolybdenum steel | Alloy Steel | Cobalt based rigid alloy steel | Aluminum Copper | Flexible Graphite | Alloy Steel | Forged cast iron | |||||||||||||||

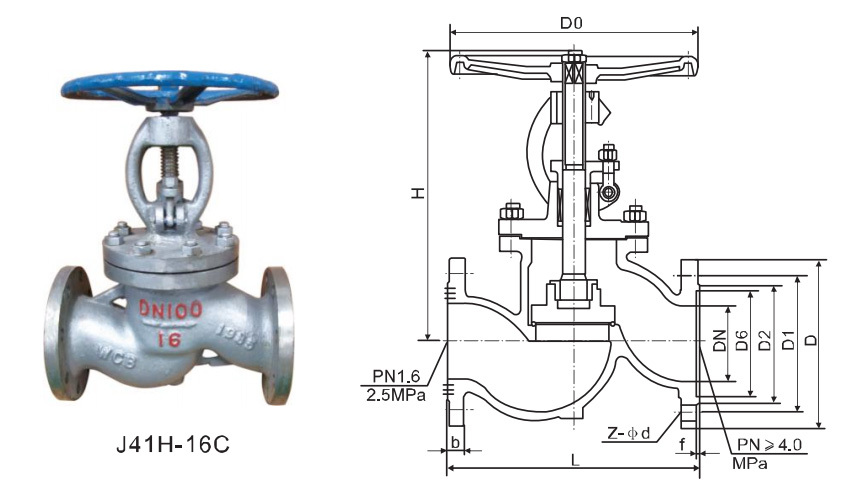

Main shape and connection size and weight

| PN (MP) |

DN (Mm) |

L | D | D1 | Д 2 | Д 6 | B | F | F2 | N-Φd | H | D0 | Wes (Kg) | ||||||||||

| 1,6 | 10 | 130 | 90 | 60 | 40 | 14 | 2 | 4-Φ14 | 198 | 120 | 4,7 | ||||||||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | 218 | 120 | 5,2 | |||||||||||||

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-Φ14 | 258 | 140 | 7,1 | |||||||||||||

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-Φ14 | 275 | 160 | 7,4 | |||||||||||||

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-Φ18 | 280 | 180 | 8,5 | |||||||||||||

| 40 | 200 | 145 | 110 | 85 | 18 | 3 | 4-Φ18 | 330 | 200 | 12,5 | |||||||||||||

| 50 | 230 | 160 | 125 | 100 | 18 | 3 | 4-Φ18 | 350 | 240 | 14 | |||||||||||||

| 65 | 290 | 180 | 145 | 120 | 18 | 3 | 4-Φ18 | 400 | 280 | 22,5 | |||||||||||||

| 80 | 310 | 195 | 160 | 135 | 20 | 3 | 8-Φ18 | 355 | 280 | 29 | |||||||||||||

| 100 | 350 | 215 | 180 | 155 | 22 | 3 | 8-Φ18 | 415 | 320 | 32,5 | |||||||||||||

| 125 | 400 | 245 | 210 | 185 | 24 | 3 | 8-Φ18 | 460 | 360 | 80 | |||||||||||||

| 150 | 480 | 280 | 240 | 210 | 24 | 3 | 8-Φ23 | 510 | 400 | 93,5 | |||||||||||||

| 200 | 600 | 335 | 295 | 265 | 26 | 3 | 12-Φ23 | 710 | 400 | 180 | |||||||||||||

| 250 | 650 | 405 | 355 | 320 | 30 | 3 | 12-Φ23 | 786 | 450 | 440 | |||||||||||||

| 300 | 750 | 460 | 410 | 375 | 30 | 3 | 12-Φ23 | 925 | 500 | 648 | |||||||||||||

| 2,5 | 10 | 130 | 90 | 60 | 40 | 16 | 2 | 4-Φ14 | 198 | 120 | 4,9 | ||||||||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | 218 | 120 | 5,4 | |||||||||||||

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-Φ14 | 258 | 140 | 7 | |||||||||||||

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-Φ14 | 275 | 160 | 7,4 | |||||||||||||

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-Φ18 | 280 | 180 | 8,5 | |||||||||||||

| 40 | 200 | 145 | 110 | 85 | 18 | 2 | 4-Φ18 | 330 | 200 | 12,5 | |||||||||||||

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-Φ18 | 350 | 240 | 16 | |||||||||||||

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-Φ18 | 400 | 280 | 25 | |||||||||||||

| 80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-Φ18 | 355 | 280 | 30 | |||||||||||||

| 100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-Φ23 | 415 | 320 | 34,5 | |||||||||||||

| 125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-Φ25 | 460 | 360 | 89 | |||||||||||||

| 150 | 480 | 300 | 250 | 218 | 30 | 3 | 8-Φ25 | 510 | 400 | 98 | |||||||||||||

| 200 | 600 | 360 | 310 | 278 | 34 | 3 | 12-Φ25 | 710 | 400 | 180 | |||||||||||||

| 250 | 650 | 425 | 370 | 332 | 36 | 3 | 12-Φ30 | 786 | 450 | 446 | |||||||||||||

| 300 | 750 | 485 | 430 | 390 | 40 | 4 | 12-Φ30 | 952 | 500 | 654 | |||||||||||||

| 4,0 | 10 | 130 | 90 | 60 | 40 | 35 | 16 | 2 | 4 | 4-Φ14 | 198 | 120 | 4,9 | ||||||||||

| 15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-Φ14 | 233 | 120 | 5,7 | |||||||||||

| 20 | 150 | 105 | 75 | 55 | 51 | 16 | 2 | 4 | 4-Φ14 | 275 | 140 | 7 | |||||||||||

| 25 | 160 | 115 | 85 | 65 | 58 | 16 | 2 | 4 | 4-Φ14 | 285 | 160 | 8,8 | |||||||||||

| 32 | 180 | 135 | 100 | 78 | 66 | 18 | 2 | 4 | 4-Φ18 | 302 | 180 | 11,8 | |||||||||||

| 40 | 200 | 145 | 110 | 85 | 76 | 18 | 3 | 4 | 4-Φ18 | 355 | 200 | 16,5 | |||||||||||

| 50 | 230 | 160 | 125 | 100 | 88 | 20 | 3 | 4 | 4-Φ18 | 373 | 240 | 24 | |||||||||||

| 65 | 290 | 180 | 145 | 120 | 110 | 22 | 3 | 4 | 8-Φ18 | 408 | 280 | 33 | |||||||||||

| 80 | 310 | 195 | 160 | 135 | 121 | 22 | 3 | 4 | 8-Φ18 | 436 | 320 | 44 | |||||||||||

| 100 | 350 | 230 | 190 | 160 | 150 | 24 | 3 | 4,5 | 8-Φ23 | 480 | 360 | 60 | |||||||||||

| 125 | 400 | 270 | 220 | 188 | 176 | 28 | 3 | 4,5 | 8-Φ25 | 558 | 400 | 89 | |||||||||||

| 150 | 480 | 300 | 250 | 218 | 204 | 30 | 3 | 4,5 | 8-Φ25 | 611 | 400 | 98 | |||||||||||

| 200 | 600 | 375 | 320 | 282 | 260 | 38 | 3 | 4,5 | 12-Φ30 | 720 | 400 | 190 | |||||||||||

Products Message

We will contact you within one working day. Please pay attention to your email.