Steam trap

Keywords:

Included in the category:

Product Description

Principle of action

When the vapor condenses, the evaporation enthalpy is released to form a condensate that contains only the enthalpy of saturated water. In order to ensure greater heat transfer efficiency of the system, condensate must be excluded from the system. Air and other non-condensable gases carried in water should also be excluded from the system to form a layer of thermal resistance on the surfaces of steam and heat exchange. The main function of the catching valve is to release condensate, air and carbon dioxide gas in the steam system as soon as possible, while at the same time, to a greater extent, automatically preventing the leakage of steam.

According to the different principles of action of dexterous valves can be divided into the following three types: mechanical type, which acts according to the change of the liquid level of condensate in the steam trap, thermostatic type, the action according to the change of liquid temperature, thermal dynamics, depends on the change of the thermodynamic properties of the liquid, When the drainage capacity of one of the steam traps cannot meet the requirements, several steam traps can be installed in parallel.

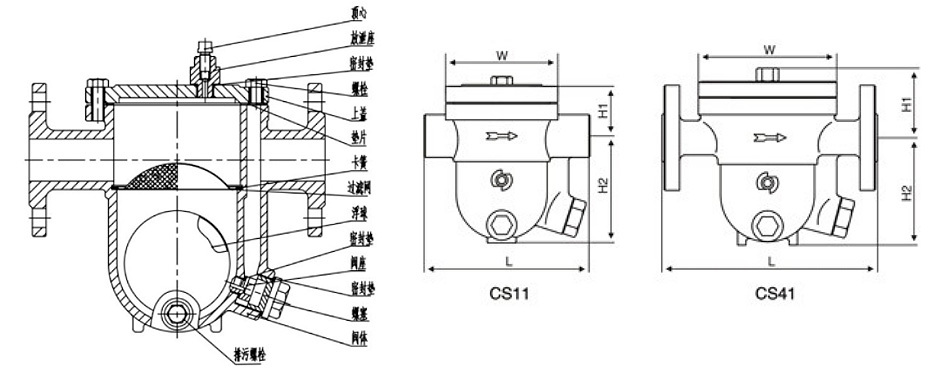

There is no arm or other equipment connected inside the free floating ball CS41H steam catching valve, the free floating ball is fully driven depending on the fluid buoyancy. The distance between the free float and the valve mouthpiece is adjusted synchronously according to the amount of condensate entering the valve body. The float itself acts as a valve to adjust the size and closing of the valve mouthpiece. As a free float, the high-precision grinding hollow ball is a valve, and the entire surface of the float can be used as the sealing surface of the valve. Since the float moves under the effect of fluid buoyancy in the valve body, and the level of condensate in the steam trap is always higher than that of the valve mouth, the valve mouth is always in the fluid compaction state, which can ensure no steam leakage. It is because of this design that the float valve seat is more stable and better protection from sealing. The 3-point support contains two guide points that can completely close the valve mouthpiece. These two guide points plus a 3-point support in which the valve mouthpiece becomes a float. A water-melting valve with this 3-point bearing structure can ensure that there is no leakage of steam (or air or gas) when the amount of condensate is very small.

Free Floating Ball Steam Trap CS41H Characteristics:

① The continuous discharge of the saturated condensed water heating equipment will not accumulate, resulting in higher thermal efficiency;

② This does not affect the change in steam pressure. The float can automatically adjust the opening of the valve hole, work continuously and work stably;

③ Good drainage air performance, automatic or manual emptying device, no air blocking, smooth operation and no noise.

Material

|

Valve body |

Cast iron/carbon steel |

Valve cover |

Cast iron/carbon steel |

|

Flood |

Stainless Steel |

Valve Seat |

Stainless Steel |

|

Proclamation |

Stainless Steel Metal Winding |

Built-in filter |

Stainless Steel |

Products Message

We will contact you within one working day. Please pay attention to your email.