Butterfly check valve(Clamp check valve)

Keywords:

Included in the category:

Product Description

Introduction

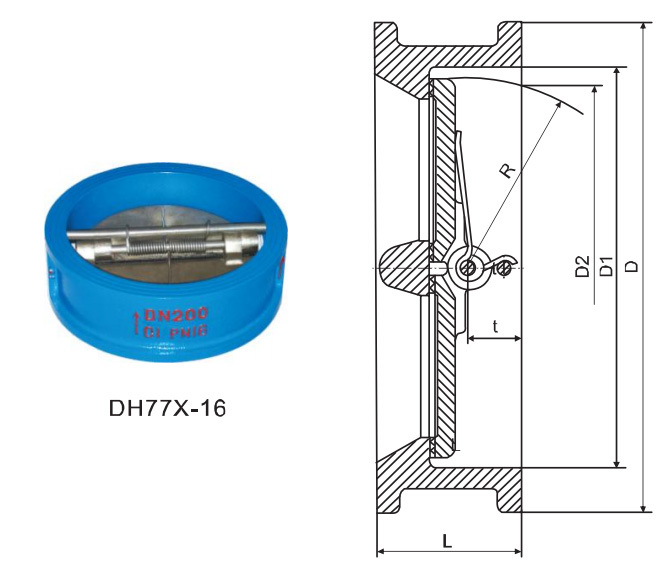

The splint type check valve adopts foreign advanced structural design and conforms to relevant international standards. It is an energy-saving product. This product has good check performance, safety, reliability, and small flow resistance. It is mainly used as a check valve in petroleum, chemical, food, medicine, textile, paper making, water supply and drainage, freezing and energy systems.

Performance specification

| Numerical diameter DN(mm) | 50(2 inch) to 700(28 inch) | 50(20) to 450(18 inches) | |||||||||||||||||||

| Ng pass PN(MPa) | 1,0 | 1,6 | |||||||||||||||||||

| Test pressure (MP) |

Housing | 1,5 | 2,4 | ||||||||||||||||||

| Seal | 1,1 | 1,76 | |||||||||||||||||||

| Applicable temperature °C | -15 to 150 | ||||||||||||||||||||

| Applicable media | Fresh water, waste water, air, vapors, food, medicine, various oils, acids, etc. D. | ||||||||||||||||||||

Main parts material

| Valve body | Valve plate | Rotary Shaft | Rubber seat | Spring | ||||

| Material Name | Code name | Material Name | Code name | Material Name | Material Name | Code name | Applicable temperature °C | Material Name |

| Grey Cast Iron | Z | Galvanic cast iron | 1 | Stainless Steel | Ethylene-propylene rubber | Х 3 | From − 46 to 121 Short time From-50 to 150 |

Stainless Steel |

| Cast iron with ball-shaped ink | Q | Aluminum Bronze | 2 | Neoprene rubber | Х 4 | From-29 to 99 Short time From-35 to 113 |

||

| Carbon Steel | With | ZG1Cr13Ni9T Stainless Steel |

Nitrile Rubber | Х 5 | From-23 to 82 Short time From-23 to 93 |

|||

| Stainless Steel | П | Stainless Steel CF8M | 5 | Neoprene rubber | X7 | -23 to 150 | ||

| Stainless Steel CF8M | 7 | |||||||

Table of main sizes and weight

| DN | D | D1 | Д 2 | L | P | T | Weight (Kg) |

|||||||||||||||||||||

| Mm | Deum | |||||||||||||||||||||||||||

| 50 | 2 inch | 107 | 65 | 43,3 | 43 | 28,2 | 19 | 1,5 | ||||||||||||||||||||

| 65 | 25 | 127 | 80 | 60,2 | 46 | 36,1 | 20 | 2,4 | ||||||||||||||||||||

| 80 | 3 inches | 142 | 94 | 66,4 | 64 | 43,4 | 28 | 3,6 | ||||||||||||||||||||

| 100 | 4 inches | 162 | 117 | 90,8 | 64 | 52,8 | 27 | 5,7 | ||||||||||||||||||||

| 125 | 5 inch | 192 | 145 | 116,9 | 70 | 65,7 | 30 | 7,3 | ||||||||||||||||||||

| 150 | 6 inch | 218 | 170 | 144,6 | 76 | 78,6 | 31 | 9,0 | ||||||||||||||||||||

| 200 | 8 inch | 273 | 224 | 198,2 | 89 | 104,4 | 33 | 17 | ||||||||||||||||||||

| 250 | 10 inch | 328 | 265 | 233,7 | 114 | 127 | 50 | 26 | ||||||||||||||||||||

| 300 | 12 inch | 378 | 310 | 283,9 | 114 | 148,3 | 43 | 42 | ||||||||||||||||||||

| 350 | 14 inch | 438 | 360 | 332,9 | 127 | 172,4 | 45 | 55 | ||||||||||||||||||||

| 400 | 16 inch | 489 | 410 | 381,0 | 140 | 197,4 | 52 | 75 | ||||||||||||||||||||

| 450 | 18 inch | 539/555 | 450 | 419,9 | 152 | 217,8 | 58 | 101/107 | ||||||||||||||||||||

| 500 | 20 inch | 594 | 505 | 467,8 | 152 | 241 | 58 | 111 | ||||||||||||||||||||

| 600 | 24 inches | 690 | 624 | 572,6 | 178 | 295,4 | 73 | 172 | ||||||||||||||||||||

| 700 | 28 inch | 800 | 720 | 680 | 229 | 354 | 98 | 219 | ||||||||||||||||||||

Introduction

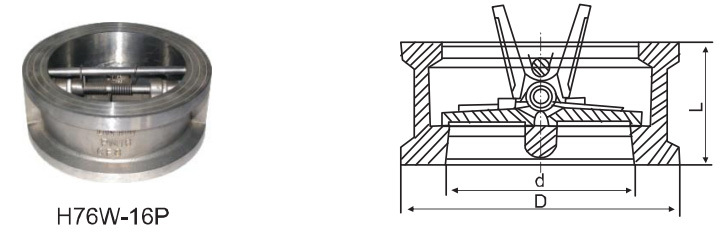

The double-disc butterfly check valve is used to prevent the backflow of media. It can be applied to water, steam, oil, nitric acid, strong oxidizing media and urea and other media.

Features

1, the double-disc butterfly check valve structure length is short, its structure length is only 1/4 to 1/8 of the traditional flange check valve;

2, small volume and light weight its weight is only 114~1/20:3 of the traditional flanged check valve, the clamping double disc butterfly check valve disc close fast water hammer pressure is small 4, horizontal pipelines and vertical pipelines can be used easy to install 5, the clamping double disc butterfly check valve flow to the smooth fluid resistance

6, sensitive sealing performance is good

7. The clamping double disc butterfly check valve has short disc stroke and small impact force

8, the overall structure is simple, compact and beautiful

9, long service life and high reliability.

Performance specification

| Part Name | Material | |||||||||||||||||||||||||||||||||||||||||

| Valve body | DSDP | ZG1Gr-18Ni9Ti | CF8 | CF3 | ZG1GM8 Ni12Mo2Ti |

CF8M | CF3M | |||||||||||||||||||||||||||||||||||

| Valves, Saddles, Springs | 2Cr13 | 1Gr18Ni9Ti | 0 gr18ni9 (304) | 00 gr18Ni10 (304l) | 1Gr18Ni-12Mo2Ti | 0Gr18Ni12-Mo2(310) | 00Gr17Ni14-Mo2(316L) | |||||||||||||||||||||||||||||||||||

| Applicable media | Water, steam. Oil products | Nitric acid and other rotten media | Strong oxidizing environment | Acetate and other aggressive environments | Corrosive media such as urea | |||||||||||||||||||||||||||||||||||||

| Applicable temperature "C | <450 | <200 | ||||||||||||||||||||||||||||||||||||||||

Table of main sizes and weight

| PN (MIP) | DN (Mm) |

L | D | Д 3 | Д 2 | Weight (kg) | Central garden diameter D1 |

Number of bolts | Diameter depth | Zero bolt length L1 | ||||||||||||||||||||||||||||||||

| 1,0 | 50 | 60 | 108 | 56 | 51 | 2 | 125 | 4 | M16 | 150 | ||||||||||||||||||||||||||||||||

| 65 | 67 | 128 | 73 | 65 | 3 | 145 | 4 | M16 | 155 | |||||||||||||||||||||||||||||||||

| 80 | 73 | 142 | 88 | 80 | 4 | 160 | 8 | M16 | 160 | |||||||||||||||||||||||||||||||||

| 100 | 73 | 162 | 108 | 102 | 6 | 180 | 8 | M16 | 165 | |||||||||||||||||||||||||||||||||

| 125 | 86 | 192 | 132 | 127 | 8 | 210 | 8 | M16 | 180 | |||||||||||||||||||||||||||||||||

| 150 | 98 | 218 | 160 | 152 | 13 | 240 | 8 | M20 | 205 | |||||||||||||||||||||||||||||||||

| 200 | 127 | 273 | 210 | 203 | 24 | 295 | 8 | M20 | 235 | |||||||||||||||||||||||||||||||||

| 250 | 146 | 328 | 266 | 254 | 37 | 350 | 12 | M20 | 255 | |||||||||||||||||||||||||||||||||

| 300 | 181 | 378 | 310 | 305 | 50 | 400 | 12 | M20 | 290 | |||||||||||||||||||||||||||||||||

| 350 | 184 | 438 | 355 | 350 | 76 | 460 | 16 | M20 | 295 | |||||||||||||||||||||||||||||||||

| 400 | 191 | 489 | 405 | 400 | 110 | 515 | 16 | M24 | 310 | |||||||||||||||||||||||||||||||||

| 450 | 203 | 539 | 455 | 450 | 135 | 565 | 20 | M24 | 325 | |||||||||||||||||||||||||||||||||

| 500 | 219 | 594 | 505 | 500 | 158 | 620 | 20 | M24 | 345 | |||||||||||||||||||||||||||||||||

| 600 | 222 | 696 | 605 | 600 | 320 | 725 | 20 | M27 | 355 | |||||||||||||||||||||||||||||||||

| 700 | 305 | 811 | 700 | 695 | 380 | 840 | 24 | M27 | 440 | |||||||||||||||||||||||||||||||||

| 800 | 305 | 918 | 800 | 796 | 560 | 950 | 24 | M30 | 450 | |||||||||||||||||||||||||||||||||

| 900 | 368 | 1018 | 903 | 898 | 640 | 1050 | 28 | M30 | 520 | |||||||||||||||||||||||||||||||||

| 1000 | 432 | 1124 | 1055 | 1050 | 900 | 1160 | 28 | M33 | 590 | |||||||||||||||||||||||||||||||||

| 1200 | 524 | 1340 | 1205 | 1200 | 1400 | 1380 | 32 | M36 | 695 | |||||||||||||||||||||||||||||||||

Products Message

We will contact you within one working day. Please pay attention to your email.