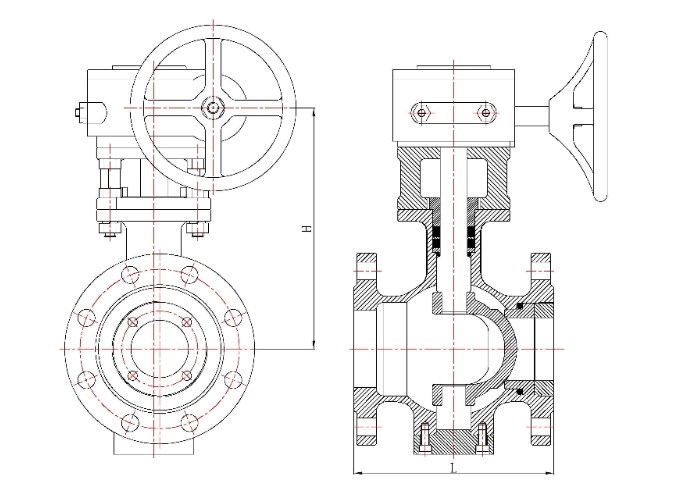

Eccentric half ball valve

Keywords:

Included in the category:

Product Description

After the pressure of the working condition device system is relieved, the valve can be checked and repaired online. During maintenance, it is only necessary to open the valve cover to lift the spherical crown and support body without removing the entire valve from the pipeline. According to the needs of users, the ball is changed into different alloys. The matching of bimetal sealing ring can be used for different industrial sectors that require strict sealing, such as wear resistance, corrosion resistance and high temperature resistance.

Working principle

The eccentric half ball valve is the crystallization of the spiritual change of the traditional ball valve. It fixes the metal ball cap on the eccentric ball and realizes the opening and closing of the valve through the 90-degree rotation of the eccentric crankshaft. The metal valve seat contacting the sealing surface of the metal ball cap floats in the axial and radial directions to compensate the matching error between the ball cap and the valve seat. The simple and reliable structure and effective sealing method make it not only a more advantageous alternative to the gate valve, and can be applied to the gate valve can not be used in the system. It can be popularized and applied to petroleum, chemical, electric power and metallurgical industries. Its core technology is the first in China, with unique design and novel structure. The valve structure adopts the principle of eccentric tightening, and the purpose of tightening, adjusting and closing is achieved through the transmission mechanism. The sealing ring and the spherical crown are both metal surface ring with hard surface contact sealing. When the double eccentric structure valve is opened, the ball is hidden in the valve cavity, the circulation load surface is large, and the valve is not flushed and has no flow resistance. When the valve core is closed, it is not washed out. When the valve core is closed, the spherical surface of the valve core is progressive along the valve seat, which has a shearing function, effectively removes scaling obstacles, and realizes reliable sealing.

It is particularly effective for transporting media that are prone to fouling. The valve hemisphere is the metal ball crown fixed on the eccentric sphere, in the sphere mounted on different alloy ball crown, valve seat also for the corresponding surfacing alloy, after special treatment, sealing surface assembly into anti-corrosion, wear-resistant, high temperature and other types, to meet the needs of different occasions. The valve seat and the ball cap have a compensation amount. When the valve seat is worn, it will rotate a little when it is closed, which can still seal reliably and prolong the service life.

Main use

1. The applicable temperature of soft-sealed eccentric hemispherical valve is -46 ℃ to 280 ℃, while the applicable temperature of hard-sealed eccentric hemispherical valve is about normal temperature to 600 ℃;

2. It is suitable for the vent valve and control valve at the bottom of the dam (high-speed flow state). Coal ash, suitable for liquid, solid two-phase mixed flow or liquid transport in the chemical reaction of crystallization or scaling of industrial pipeline transportation. According to the different media and temperature requirements required by customers, the spherical cap is made of chromium molybdenum and vanadium alloy, and the valve seat is surfacing with chromium molybdenum alloy, chromium alloy and stainless steel alloy to meet the needs of different slurry transportation;

3, suitable for pump delivery system valves, such as pressurized systems, central air conditioning systems, urban heating and other strict requirements of the system.

4. Suitable for water system, gas system, natural gas system, seawater, oil, alumina and other pipeline facilities.

| Nominal pressure PN(Mpa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

| Maximum working pressure at room temperature (Mpa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

| Shell strength test pressure (Mpa) |

1.0 |

1.5 |

2.4 |

3.8 |

6.0 |

| Air seal test pressure (Mpa) |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

| High pressure seal test pressure (Mpa) |

0.7 |

1.1 |

1.76 |

2.75 |

4.4 |

| leakage rate |

<0.1 × DNmm ³/s (in accordance with GB/T13927-2008) |

||||

| Applicable media |

Natural gas, steam, oil, acids, alkalis, coal ash, waste residue, mud, granular and fiber-containing media. |

||||

| Serial Number |

Part Name |

Material Name |

|||

| 1 |

Valve body |

WCB |

ZG1Cr18Ni9Ti |

ZG0Cr18Ni12Mo2Ti |

ZG15Cr1Mo1V |

| 2 |

Rear lid |

Q235A |

1Cr18Ni9Ti |

0Cr18Ni12Mo2Ti |

25Cr2Mo1V |

| 3 |

Shaft sleeve |

SF-1 |

FB090 |

FB316 |

FB090 |

| 4 |

Lower Stem |

2Cr13 |

1Cr18Ni9Ti |

0Cr18Ni12Mo2Ti |

1Cr18Ni9Ti |

| 5 |

Sphere |

WCB |

ZG1Cr18Ni9Ti |

ZG0Cr18Ni12Mo2Ti |

ZG15Cr1Mo1V |

| 6 |

Pressure plate |

Q235A |

1Cr18Ni9Ti |

0Cr18Ni12Mo2Ti |

25Cr2Mo1V |

| 7 |

Valve seat |

Q235A PTFE/ |

1Cr18Ni9Ti/PTFE |

0Cr18Ni12Mo2Ti/PTFE |

25Cr2Mo1V/PTFE |

| 8 |

ball crown |

1Cr18Ni9Ti |

1Cr18Ni9Ti |

0Cr18Ni12Mo2Ti |

1Cr18Ni9Ti |

| Nominal diameter DN(mm) |

Dimensions (mm) |

|

| L |

H |

|

| 50 |

178 |

210 |

| 65 |

190 |

215 |

| 80 |

203 |

245 |

| 100 |

229 |

265 |

| 125 |

254 |

290 |

| 150 |

267 |

315 |

| 200 |

292 |

360 |

| 250 |

330 |

380 |

| 300 |

356 |

450 |

| 350 |

381 |

500 |

| 400 |

406 |

570 |

| 450 |

432 |

640 |

| 500 |

457 |

700 |

| 600 |

508 |

760 |

| 700 |

610 |

830 |

| 800 |

660 |

920 |

| 900 |

711 |

1050 |

| 1000 |

811 |

1185 |

| 1200 |

1015 |

1325 |

Products Message

We will contact you within one working day. Please pay attention to your email.