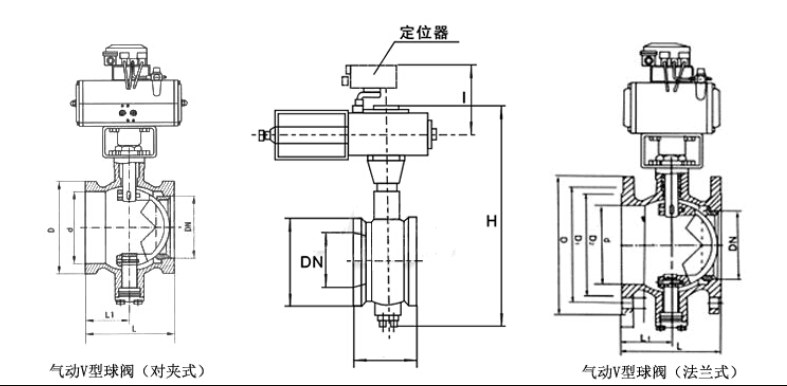

Pneumatic V-type ball valve

Keywords:

Included in the category:

Product Description

Introduction

Pneumatic V-type ball valve has double-acting and single-acting (spring return), and adopts rack and pinion structure transmission, which is safer and more reliable; large-diameter valve adopts AW series pneumatic actuator, shift fork structure transmission, reasonable structure and output torque Big.

Pneumatic V-type ball valve according to the sealing performance is divided into soft seal and hard seal; according to the adjustment mode is divided into regulation type and cut-off type, cut-off type according to the role of the form of single-acting and double-acting, regulating type for double-acting. The unique advantage of the single-acting type is that once the power source fails, the ball valve will automatically be in the closed or open position according to the requirements of the control system.

Working principle

Pneumatic V-shaped ball valve has a special shape of fixed V-shaped notch ball and adjustable metal valve seat structure. When the valve is closed, the V-shaped notch and the valve seat form a wedge-shaped shearing effect, which can prevent the dirt between the ball and the valve seat. The phenomenon of seizure is self-cleaning. It is especially suitable for media containing fiber slurry, sewage and viscous particles. It can be continuously adjusted with valve positioner, and has small flow resistance and wide adjustment range, is a wide range of high-quality control valve.

Main technical parameters

| Valve body form |

Straight through cast ball valve |

| Nominal diameter |

DN25~400mm |

| Nominal pressure |

PN1.6、2.5、4.0、6.4 MPa |

| Flange standard |

GB、JB、HG、ANSI、JIS等 |

| Connection form |

Wafer type, flange type |

| Valve cover form |

Integral type (applicable temperature -45~400 ℃) |

| Type of gland |

Bolt compression type |

| Seal packing |

V-type PTFE filler, impregnated PTFE asbestos filler, asbestos textile filler, graphite filler |

| Spool form |

Ball type spool with V-cut |

| flow characteristics |

Approximate equal percentage (see flow characteristic curve) |

Material List of Main Parts

| Material \Material Code |

C |

P |

R |

|

| Main parts |

Valve body |

WCB |

ZG1Cr18Ni9Ti |

ZG0Cr18Ni12Mo2Ti |

| Ball Plate |

2Cr13 |

ZG1Cr18Ni9Ti |

ZG0Cr18Ni12Mo2Ti |

|

| Stem |

2Cr13 |

1Cr18Ni9Ti |

0Cr18Ni12Mo2Ti |

|

| Sealing ring |

cemented carbide |

|||

| Packing |

PTFE, soft graphite |

|||

| Applicable working conditions |

Applicable media |

Water, steam, oil |

Nitric acid |

Acetic acid |

| Applicable temperature |

-28 ℃ ~ 500 ℃ |

|||

Main outline and connection dimension

| PN(MPa) |

DN(mm) |

Dimensions (mm) |

||||||||

| L |

Interclamp connection |

Flange connection |

H |

|||||||

| D |

D |

D1 |

D2 |

D6 |

b |

Z-d |

||||

| 1.6 |

25 |

102 |

64 |

115 |

85 |

5 |

- |

14/16 |

4-14 |

233 |

| 40 |

114 |

82 |

145/150 |

110 |

85/84 |

- |

16/18 |

4-18 |

280 |

|

| 50 |

124 |

100 |

160/165 |

125 |

100/99 |

- |

16/20 |

4-18 |

362 |

|

| 65 |

145 |

118 |

180/185 |

145 |

120/188 |

- |

18/20 |

4-18 |

377 |

|

| 80 |

165 |

130 |

195/200 |

160 |

135/132 |

- |

20 |

8-18 |

410 |

|

| 100 |

194 |

155 |

215/220 |

180 |

155/150 |

- |

20/22 |

8-18 |

423 |

|

| 125 |

210 |

185 |

245/250 |

210 |

185/184 |

- |

22 |

8-18 |

436 |

|

| 150 |

229 |

216 |

280/285 |

240 |

210/211 |

- |

24 |

8-23/8-22 |

653 |

|

| 200 |

243 |

264 |

335/340 |

295 |

265/266 |

- |

26/24 |

12-23/12-22 |

703 |

|

| 250 |

297 |

328 |

405 |

355 |

320/319 |

- |

30/26 |

12-25/12-26 |

787 |

|

| 300 |

338 |

373 |

460 |

410 |

375/370 |

- |

30/28 |

12-25/12-26 |

827 |

|

| 2.5 |

25 |

102 |

64 |

115 |

85 |

65 |

- |

16 |

4-14 |

233 |

| 40 |

114 |

82 |

145/150 |

110 |

85/84 |

- |

18 |

4-18 |

280 |

|

| 50 |

124 |

100 |

160/165 |

125 |

100/99 |

- |

20 |

4-18 |

362 |

|

| 65 |

145 |

118 |

160/185 |

145 |

120/118 |

- |

22 |

8-18 |

377 |

|

| 80 |

165 |

130 |

195/200 |

160 |

135/132 |

- |

22-24 |

8-18 |

410 |

|

| 100 |

194 |

155 |

230/235 |

190 |

160/156 |

- |

24 |

8-23/8-22 |

423 |

|

| 125 |

210 |

185 |

270 |

220 |

188/184 |

- |

28/26 |

8-25/8-26 |

436 |

|

| 150 |

229 |

216 |

300 |

250 |

218/211 |

- |

30/28 |

8-25/12-26 |

653 |

|

| 200 |

243 |

264 |

360 |

310 |

278/274 |

- |

34/30 |

12-25/12-26 |

703 |

|

| 250 |

297 |

328 |

425 |

370 |

332/330 |

- |

36/32 |

12-30 |

787 |

|

| 300 |

338 |

373 |

485 |

430 |

390/389 |

- |

40/34 |

16-30 |

827 |

|

Products Message

We will contact you within one working day. Please pay attention to your email.