Electric gate valve

Keywords:

Included in the category:

Product Description

Product overview

Electric flange gate valve is widely used in petrochemical industry, thermal power plants and other oil products, water vapor pipeline for connecting or cutting off the medium in the pipeline opening and closing device.

Structural features

(1) the flow resistance is small. The internal medium channel of the valve body is straight, the medium flows in a straight line, and the flow resistance is small.

(2) Save effort when opening and closing. Compared with the cut-off valve, because whether it is open or closed, the direction of movement of the ram is perpendicular to the direction of the medium flow.

(3) The height is large and the opening and closing time is long. The opening and closing stroke of the gate is large, and the lowering is carried out by the screw.

(4) water hammer phenomenon is not easy to produce. The reason is the long closing time.

(5) The medium can flow in any direction on both sides and is easy to install. Gate valve channels are symmetrical on both sides.

(6) The structural length (the distance between the two connecting end faces of the housing) is small.

(7) the sealing surface is easy to wear, affecting the service life. When opening and closing, the two sealing surfaces of the gate and the valve seat slide with each other, which is easy to produce abrasion and wear under the action of medium pressure, which affects the sealing performance and shortens the service life.

8) The price is higher. There are many contact sealing surfaces, and the processing is more complicated, especially the sealing surface on the gate seat is not easy to process, and there are many parts,

(9) The form is simple, the structure length is short, the manufacturing process is good, and the scope of application is wide.

(10) Tight structure, good valve rigid parts, smooth passage, small lumens, stainless steel and hard alloy sealing surface, long service life, PTFE packing, reliable sealing, light and flexible operation.

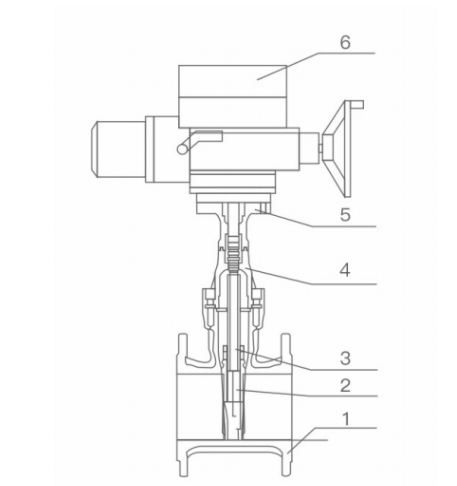

| Serial Number |

Part Name |

Materials |

| 1 |

Valve body |

Ductile iron, carbon steel |

| 2 |

Valve plate |

Ductile iron coated with EPDM or NBR |

| 3 |

Stem |

Stainless Steel |

| 4 |

Bonnet |

Ductile iron, cast steel |

| 5 |

Bracket |

Ductile iron, cast steel |

Main outline connection dimension

| DN |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

600 |

|

| L |

F4 |

150 |

170 |

180 |

190 |

200 |

210 |

230 |

150 |

270 |

290 |

310 |

330 |

350 |

390 |

| BS |

178 |

190 |

203 |

229 |

254 |

267 |

292 |

330 |

356 |

381 |

406 |

432 |

457 |

508 |

|

| F5 |

250 |

270 |

280 |

300 |

325 |

350 |

400 |

450 |

500 |

550 |

600 |

650 |

700 |

800 |

|

| H |

732 |

773 |

820 |

870 |

915 |

1003 |

1110 |

1263 |

1360 |

1550 |

1610 |

1900 |

1938 |

2120 |

|

Products Message

We will contact you within one working day. Please pay attention to your email.