Pneumatic three-piece ball valve

Keywords:

Included in the category:

Product Description

Introduction

The pneumatic actuator adopts the new AT/GT series pneumatic actuator, with double action and single action (spring return), and adopts the rack and pinion structure transmission, the performance is more safe and reliable; Large diameter valve adopts AW series pneumatic actuator, shift fork structure transmission, reasonable structure, large output torque.

Pneumatic ball valve with internal thread is composed of double (single) acting pneumatic piston actuator and internal thread ball valve. The valve body can be divided into integral, two-piece, three-piece. The seat adopts elastic sealing structure, reliable sealing, easy opening and closing. The valve stem adopts a bottom-mounted structure with reverse seal, and the valve stem will not be impacted when the valve chamber is abnormally pressurized. The pneumatic piston actuator is made of low-friction material bearing sleeve, and the inner and outer surfaces of the cylinder block are treated with hard anodic oxidation and anti-corrosion treatment, which greatly improves the service life of the cylinder.

Working principle

Pneumatic ball valve is compressed air as the power source, with the cylinder as the actuator, and with the help of electrical valve positioner, converter, solenoid valve, holding valve and other accessories to drive the valve, to achieve switching or proportional adjustment, receive the control signal of industrial automation control system to complete the adjustment of pipeline media flow, pressure, temperature and other process parameters.

Product Features

1. Manual operating mechanism can be installed at the top and bottom.

2. Gear type double piston, large output torque and small size.

3. The cylinder is made of aluminum and gold material, which is light in weight and beautiful in appearance.

4. The valve seat adopts elastic sealing structure, reliable sealing and easy opening and closing.

Main technical parameters

|

Valve body form |

Internal thread precision casting valve body |

|

Nominal diameter |

DN6~100mm |

|

Nominal pressure |

PN1.6-2.5-4.0-6.4 MPa;ANSI 150-300-600LB; It 10-20-30K |

|

Connection form |

Pipe Thread (G), Taper Thread (NPT) |

|

Valve cover form |

One-piece |

|

Type of gland |

Pressure cap tightening type |

|

Seal packing |

V-type PTFE filler, impregnated PTFE asbestos filler, asbestos textile filler, graphite filler |

|

Spool form |

O-type ball valve core |

|

flow characteristics |

Quick opening feature |

|

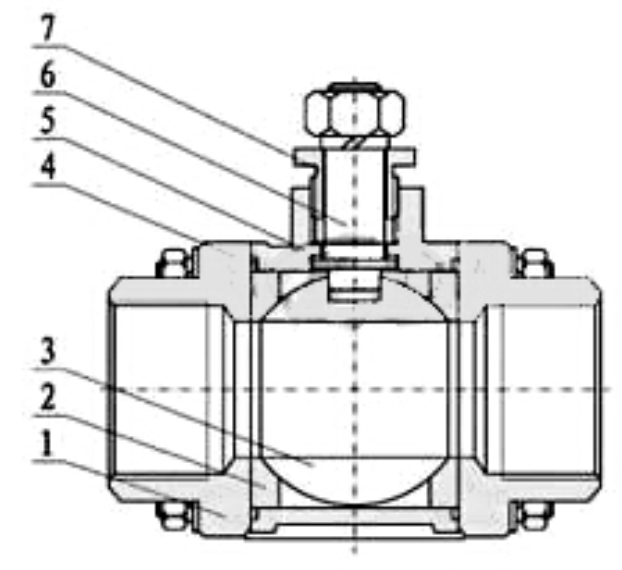

1 |

Left valve body |

WCB、CF8、CF8M、CF3M |

|

2 |

Valve seat |

PEFE、PPL、304、316 |

|

3 |

Sphere |

WCB、CF8、CF8M、CF3M |

|

4 |

Sealing ring |

PTFE/Metallic Graphite Wound Gasket |

|

5 |

Right valve body (middle valve body) |

WCB、CF8、CF8M、CF3M |

|

6 |

Stem |

2Cr13304、316、316L |

|

7 |

Packing gland |

WCB、CF8、CF8M、CF3M |

Main performance parameters

|

Test pressure (Mpa) |

Nominal pressure (Mpa) |

Pressure class |

He (K) |

|||||||

|

1.6 |

2.5 |

4.0 |

6.4 |

10.0 |

150 |

300 |

600 |

10K |

20K |

|

|

Strength test |

2.4 |

3.8 |

6.0 |

9.6 |

15.0 |

3.1 |

7.8 |

15.3 |

2.4 |

3.8 |

|

Sealing test |

1.8 |

2.8 |

4.4 |

7.0 |

11.0 |

2.2 |

5.6 |

11.2 |

1.5 |

2.8 |

|

Air tightness test |

0.5~0.7 |

|||||||||

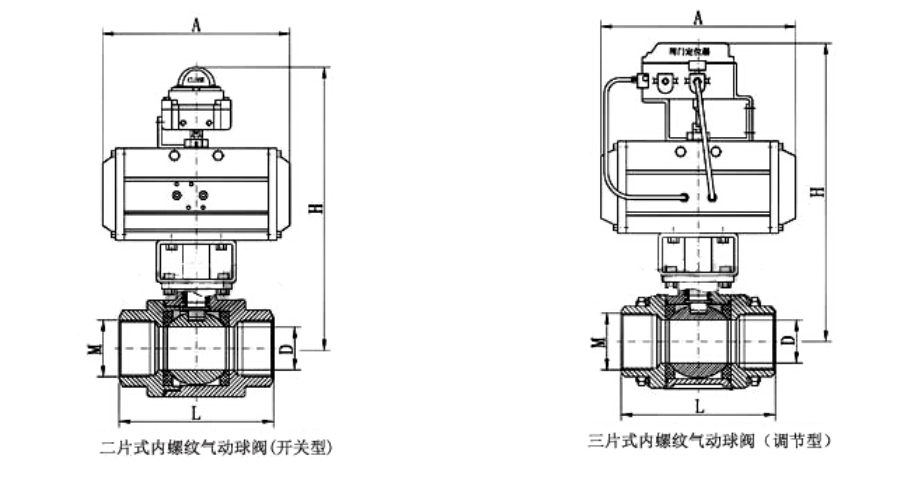

Main outline and connection dimension

|

Nominal diameter |

Internal thread connection |

|||||

|

mm |

inch |

D |

L |

H |

G |

A |

|

10 |

3/8 |

10 |

60 |

157 |

3/8 ″ |

140 |

|

15 |

1/2 |

15 |

75 |

168 |

1/2 ″ |

140 |

|

20 |

3/4 |

20 |

80 |

170 |

3/4 ″ |

140 |

|

25 |

1 |

25 |

90 |

180 |

1″ |

140 |

|

32 |

11/4 |

32 |

110 |

185 |

11/4 ″ |

164 |

|

40 |

11/2 |

38 |

125 |

200 |

11/2 ″ |

164 |

|

50 |

2 |

50 |

144 |

210 |

2″ |

190 |

|

65 |

21/2 |

64 |

186 |

230 |

21/2 ″ |

210 |

|

80 |

3 |

78 |

206 |

250 |

3″ |

247 |

|

100 |

4 |

98 |

240 |

270 |

4″ |

247 |

Products Message

We will contact you within one working day. Please pay attention to your email.