Pneumatic flange ball valve

Keywords:

Included in the category:

Product Description

Product Introduction

Pneumatic flange ball valve only need to use gas to rotate 90 degrees of operation and a small torque can be closed tightly. Completely equal body cavity for the medium to provide a small resistance, straight-through flow. It is generally believed that the ball valve is the most suitable for direct opening and closing, but recent developments have designed the ball valve so that it has throttling and flow control. The main feature of the ball valve is its own compact structure, easy operation and maintenance, suitable for water, solvents, acids and natural gas and other general working media, but also suitable for poor working conditions of the medium, such as oxygen, hydrogen peroxide, methane and ethylene. The ball valve body can be integral or combined.

Working principle

Pneumatic flange ball valve is a direct combination of GT type, AT type pneumatic piston cylinder and a 90 ° rotating ball valve. When the ball rotates 90 degrees, the inlet and outlet should be all spherical, thus cutting off the flow, and vice versa, both through-holes, so that the medium through. The full diameter of the ball cavity for the medium to provide a small resistance, straight-through flow. The rapid rotation of the pneumatic actuator 90 degrees can make the ball valve close tightly in an instant, and the direct connection between the actuator and the valve body reduces the probability of failure. Flange connection of the pipeline can maintain good sealing performance, easy to repair and replace, easy to close the pipeline.

Product Features

1. Gear type double piston, large output torque and small volume.

2. The cylinder is made of aluminum and gold material, which is light in weight and beautiful in appearance.

3. Manual operating mechanism can be installed at the top and bottom.

4. Rack type connection can adjust the opening angle and rated flow.

Performance Specification

|

Nominal diameter mm |

DN15-DN300 |

|||

|

Material code |

C |

P |

R |

|

|

Main parts |

Valve body |

WCB |

ZG1Cr18Ni9Ti |

ZG1Cr18Ni12Mo2Ti |

|

Sphere |

2Cr13 |

1Cr18Ni9Ti |

1Cr18Ni12MoTi |

|

|

Stem |

2Cr13 |

1Cr18Ni9Ti |

1Cr18Ni12MoTi |

|

|

Sealing ring |

Reinforced polytetrafluoroethylene para-polystyrene |

|||

|

Packing |

PTFE Flexible Graphite |

|||

|

Applicable working conditions |

Applicable media |

Steam, water, oil |

Nitric acid | Acetic acid |

|

Applicable temperature |

-28 ℃- 300 ℃ |

|||

|

Actuator |

Model |

DA/SR series, GTD/GTE series, QGSY series, etc. |

||

|

Air supply pressure |

0.4-0.7MPa |

|||

Technical parameters

|

Test pressure |

Nominal pressure (Mpa) |

Pressure class |

He (Mpa) |

|||||||

|

1.6 |

2.5 |

4.0 |

6.4 |

10.0 |

150 |

300 |

600 |

10K |

20K |

|

|

Strength test |

2.4 |

3.8 |

6.0 |

9.6 |

15.0 |

3.1 |

7.8 |

15.3 |

2.4 |

3.8 |

|

Sealing test |

1.8 |

2.8 |

4.4 |

7.0 |

11.0 |

2.2 |

5.6 |

11.2 |

1.5 |

2.8 |

|

Air tightness test |

0.5~0.7 |

|||||||||

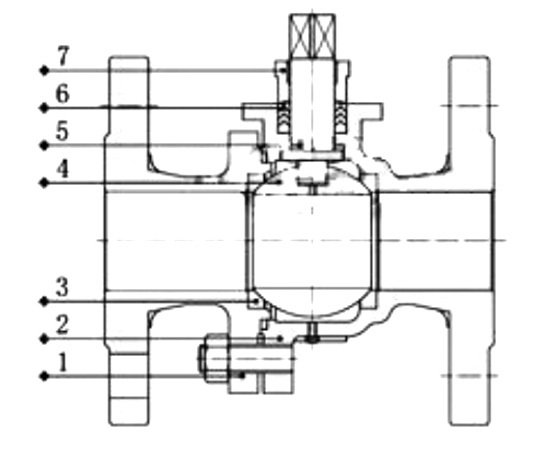

Main parts material

|

1 |

Left valve body |

WCB、CF8、CF8M、CF3M |

|

2 |

Right valve body |

WCB、CF8、CF8M、CF3M |

|

3 |

Valve seat |

PEFE、PPL、304、316 |

|

4 |

Sphere |

2Cr13、304、316 |

|

5 |

Stem |

2Cr13、304、316 |

|

6 |

Seal packing |

PTFE/Flexible Graphite |

|

7 |

Packing gland |

WCB、CF8、CF8M、CF3M |

|

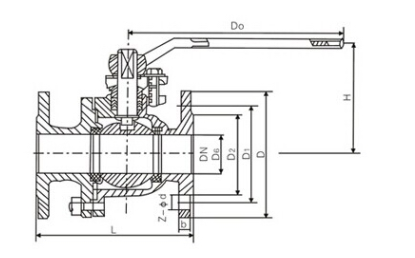

1.6MPa |

DN |

L |

D |

D1 |

D2 |

b |

N-φd |

H |

D0 |

|

Raise face flange |

15 |

130 |

95 |

65 |

45 |

14 |

4-14 |

78 |

140 |

|

20 |

140 |

105 |

75 |

55 |

14 |

4-14 |

84 |

160 |

|

|

25 |

150 |

115 |

85 |

65 |

14 |

4-14 |

95 |

180 |

|

|

32 |

165 |

135 |

100 |

78 |

16 |

4-18 |

150 |

250 |

|

|

40 |

180 |

145 |

110 |

85 |

16 |

4-18 |

150 |

300 |

|

|

50 |

200 |

160 |

125 |

100 |

18 |

4-18 |

170 |

350 |

|

|

65 |

220 |

180 |

145 |

120 |

20 |

4-18 |

195 |

350 |

|

|

80 |

250 |

195 |

160 |

135 |

20 |

8-18 |

215 |

400 |

|

|

100 |

280 |

215 |

180 |

155 |

20 |

8-18 |

250 |

500 |

|

|

125 |

320 |

245 |

210 |

185 |

22 |

8-18 |

265 |

600 |

|

|

150 |

360 |

280 |

240 |

210 |

24 |

8-23 |

270 |

800 |

|

|

200 |

400 |

335 |

295 |

265 |

26 |

12-23 |

330 |

1200 |

|

|

2.5MPa |

15 |

130 |

95 |

65 |

45 |

16 |

4-14 |

103 |

140 |

|

Raise face flange |

20 |

140 |

105 |

75 |

55 |

16 |

4-14 |

112 |

160 |

|

25 |

150 |

115 |

85 |

65 |

16 |

4-14 |

123 |

180 |

|

|

32 |

165 |

135 |

100 |

78 |

18 |

4-18 |

150 |

250 |

|

|

40 |

180 |

145 |

110 |

85 |

18 |

4-18 |

156 |

300 |

|

|

50 |

200 |

160 |

125 |

100 |

20 |

8-18 |

172 |

350 |

|

|

65 |

220 |

180 |

145 |

120 |

22 |

8-18 |

197 |

350 |

|

|

4.0MPa |

DN |

L |

D |

D1 |

D2 |

D6 |

b |

N-φd |

H |

|

Concave-convex flange |

15 |

130 |

95 |

65 |

45 |

40 |

16 |

4-14 |

103 |

|

20 |

140 |

105 |

75 |

55 |

51 |

16 |

4-14 |

112 |

|

|

25 |

150 |

115 |

85 |

65 |

58 |

16 |

4-14 |

123 |

|

|

32 |

180 |

135 |

100 |

78 |

66 |

18 |

4-18 |

150 |

|

|

40 |

200 |

145 |

110 |

85 |

76 |

18 |

4-18 |

156 |

|

|

50 |

220 |

160 |

125 |

100 |

88 |

20 |

4-18 |

172 |

|

|

65 |

250 |

180 |

145 |

120 |

110 |

22 |

8-18 |

197 |

|

|

80 |

280 |

195 |

160 |

135 |

121 |

22 |

8-18 |

222 |

|

|

100 |

320 |

230 |

190 |

160 |

150 |

24 |

8-23 |

253 |

|

|

125 |

400 |

270 |

220 |

188 |

176 |

28 |

8-25 |

275 |

|

|

150 |

400 |

300 |

250 |

218 |

204 |

30 |

8-25 |

286 |

|

|

200 |

550 |

375 |

320 |

282 |

260 |

38 |

12-30 |

340 |

|

|

6.4MPa |

15 |

165 |

105 |

75 |

55 |

40 |

18 |

4-14 |

105 |

|

Concave-convex flange |

20 |

190 |

125 |

90 |

68 |

51 |

20 |

4-18 |

125 |

|

25 |

216 |

135 |

100 |

78 |

58 |

22 |

4-18 |

135 |

|

|

32 |

229 |

150 |

110 |

82 |

66 |

24 |

4-23 |

150 |

|

|

40 |

241 |

165 |

125 |

95 |

76 |

24 |

4-23 |

165 |

|

|

50 |

292 |

175 |

135 |

105 |

88 |

26 |

4-23 |

175 |

|

|

65 |

330 |

200 |

160 |

130 |

110 |

28 |

8-23 |

200 |

|

|

80 |

356 |

210 |

170 |

140 |

121 |

30 |

8-23 |

210 |

|

|

100 |

432 |

250 |

200 |

168 |

150 |

32 |

8-25 |

250 |

Products Message

We will contact you within one working day. Please pay attention to your email.