Electric flange ball valve

Keywords:

Included in the category:

Product Description

Overview

Q941F Electric flange ball valve adopts integrated structure, with input control signal (4 ~ 20mA DC or 1~5V DC) and single-phase power supply to control operation. It has strong function, small volume, light and pleasant, reliable performance, simple matching and circulation ability, and is especially suitable for occasions where the medium is viscous, particle and fiber. At present, the valve is widely used in food, environmental protection, light industry, petroleum, paper, chemical teaching and scientific research equipment, electric power and other industries in the industrial automatic control system.

Q941F Electric flange ball valve is suitable for two cut-off, adjust the occasion. The electric switch type ball valve is connected with the actuator in a direct connection mode. The electric actuator has a built-in servo system and does not need to be equipped with a servo amplifier. The operation can be controlled by inputting 4-20mA signal and 220VAC power supply. It has the advantages of simple connection, compact structure, small size, light weight, low resistance, stable and reliable action, etc.

Working principle

Q941F electric flanged ball valve is powered by DC24V, AC220V or AC380V power supply voltage, directly receives unified standard signals (4-20mA DC, 0-10mA DC or 1-5V DC, 0-10V DC), converts this into displacement corresponding to the input signal, moves with angular displacement (0~90), and changes the rotation opening of the ball core. Therefore, a certain input signal corresponds to a certain position and opening, achieve proportional adjustment action. (The two-position switch type accepts DC24V, AC220V or AC380V power supply voltage as power, realizes the switching action through the positive and negative rotation of the motor, and outputs the switch valve position indication signal at the same time).

Features

1, easy to install, can be installed in any direction in any part of the pipeline.

2, fine small electric actuator has a variety of power to choose from, more explosion-proof electric equipment.

3. The passage in the valve body is smooth and smooth, which can transport viscous fluid, slurry and solid particles.

4, direct connection mode, electric actuator built-in servo system, no need to match the servo amplifier.

5. There is no bracket connection between the ball valve and the electric actuator, and the integrated appearance is compact, reducing the equipment space.

6. The sealing material is polytetrafluoroethylene, etc., which has good self-lubrication and small friction loss with the ball, so the ball valve has a long service life.

Main technical parameters

|

Valve body form |

straight through casting valve |

|

Nominal diameter |

DN15~300mm |

|

Nominal pressure |

PN1.6-2.5-4.0-6.4 MPa;ANSI 150-300LB; It 10-20-30K |

|

Flange standard |

JIS、ANSI、GB、JB、HG等 |

|

Connection form |

Flange type, welding type, thread type |

|

Valve cover form |

One-piece |

|

Type of gland |

Pressure plate pressing type |

|

Seal packing |

V-type PTFE packing, flexible graphite packing, etc. |

|

Spool form |

O-Ball Spool |

|

flow characteristics |

Approximate quick opening type |

main performance index

|

Nominal diameter DN(mm) |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

|

Rated flow coefficient KV |

21 |

38 |

72 |

112 |

170 |

273 |

384 |

512 |

940 |

1452 |

2222 |

3589 |

5128 |

7359 |

|

Allowable pressure difference (MPa) |

≤ Nominal pressure |

|||||||||||||

|

Action range |

0~90°、0~360° |

|||||||||||||

|

Leakage Q |

According to GB/T4213-92, less than rated KV0.01% |

|||||||||||||

|

basic error |

±1% |

|||||||||||||

|

Return difference |

±1% |

|||||||||||||

|

dead zone |

≤1% |

|||||||||||||

|

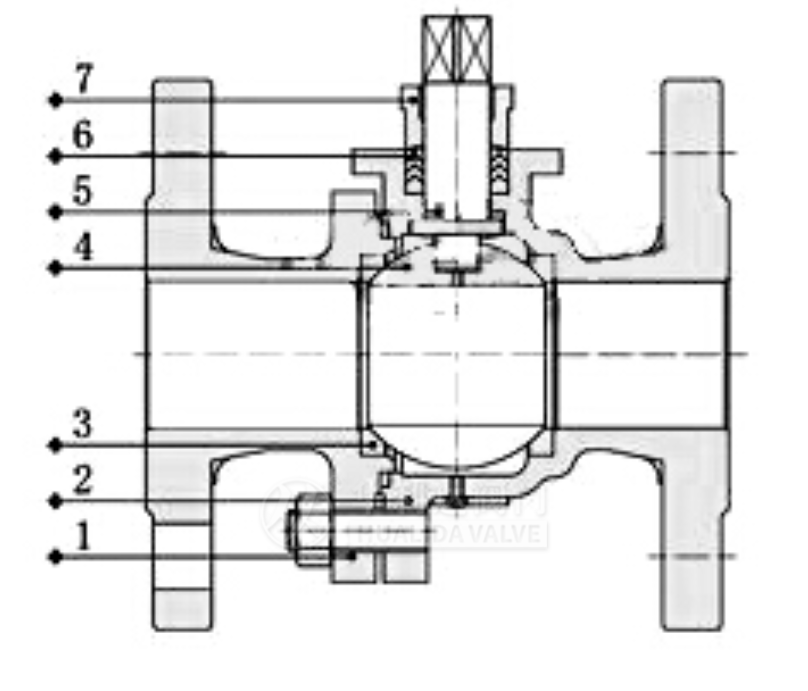

1 |

Left valve body |

WCB、CF8、CF8M、CF3M |

|

2 |

Right valve body |

WCB、CF8、CF8M、CF3M |

|

3 |

Valve seat |

PEFE、PPL、304、316 |

|

4 |

Sphere |

2Cr13、304、316 |

|

5 |

Stem |

2Cr13、304、316 |

|

6 |

Seal packing |

PTFE/Flexible Graphite |

|

7 |

Packing gland |

WCB、CF8、CF8M、CF3M |

|

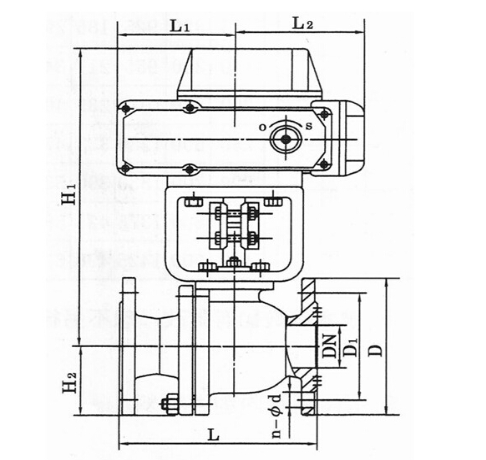

Nominal diameter DN(mm) |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

|

L |

130 |

140 |

150 |

165 |

180 |

200 |

220 |

250 |

280 |

320 |

360 |

400 |

630 |

750 |

|

H |

44.5 |

49 |

55 |

65 |

65 |

75 |

90 |

95 |

115 |

127 |

140 |

172.5 |

310 |

350 |

|

H1 |

Depending on the actuator |

|||||||||||||

|

D |

95 |

105 |

115 |

140 |

150 |

165 |

185 |

200 |

220 |

250 |

285 |

340 |

405 |

460 |

|

D1 |

65 |

75 |

85 |

100 |

110 |

125 |

145 |

160 |

180 |

210 |

240 |

295 |

355 |

410 |

|

D2 |

46 |

56 |

65 |

76 |

84 |

99 |

118 |

132 |

156 |

184 |

211 |

266 |

319 |

370 |

|

N-φd |

4-14 |

4-14 |

4-14 |

4-18 |

4-18 |

4-18 |

4-18 |

8-18 |

8-18 |

8-18 |

8-22 |

12-22 |

12-26 |

12-26 |

|

A、A1 |

Depending on the torque required by the valve, the configuration model is different, and the dimensions are different. |

|||||||||||||

Products Message

We will contact you within one working day. Please pay attention to your email.