Insulated ball valve

Keywords:

Included in the category:

Product Description

Introduction

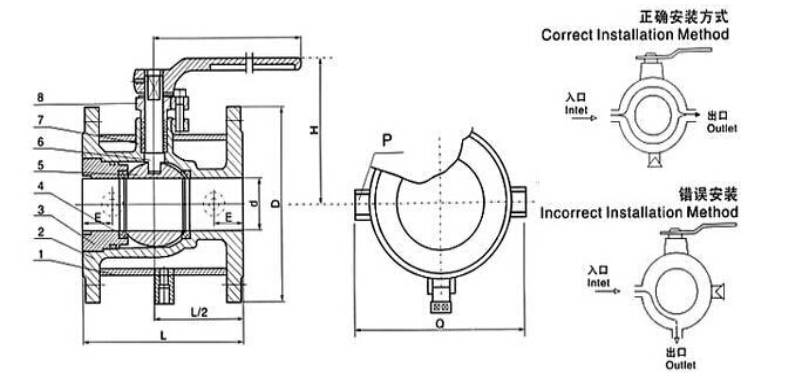

The product has good thermal insulation and cold protection characteristics, and the diameter of the valve and the diameter of the pipe, the medium is a straight line flow, the resistance is small, the most suitable for easy solidification, high viscosity liquid media. At the same time, it can effectively reduce the heat loss of the pipeline medium. The whole stainless steel material, with high corrosion resistance, no rust, no problem under normal use for 20 years. Integrated jacket design, more uniform heat preservation, cold protection. Jacket, body outside welded with jacket nozzle, allow steam or cold water up to 1MPa. It is mainly used in petroleum, chemical, pharmaceutical, food and other systems to transport high-viscosity media that will solidify at room temperature. Jacket insulated ball valve and gate valve are the same type of valve, the difference is that the closing part of the insulated ball valve is a ball, and the ball rotates around the center line of the valve body to achieve the opening and closing of a valve. Ball valves are mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. Is a new type of valve widely used in recent years, such valves are generally installed horizontally.

Advantage

1. The fluid resistance is small, and its resistance coefficient is equal to that of the pipe segment of the same length.

2. Simple structure, small size, light weight.

3. Tight and reliable, the sealing surface material of the ball valve is widely used in plastic, good sealing, and has also been widely used in vacuum systems.

4. Easy to operate, open and close quickly, from full open to full close as long as the rotation of 90 degrees, easy to remote control.

5. Easy maintenance, ball valve structure is simple, the sealing ring is generally active, disassembly and replacement are more convenient.

6. When fully open or fully closed, the sealing surface of the ball and the seat is isolated from the medium, and the medium will not cause erosion of the valve sealing surface when it passes through.

7. Wide range of application, small diameter to a few millimeters, large to a few meters, from high vacuum to high pressure can be applied.

Material table of main parts

|

Serial Number |

Part Name |

Material |

Serial Number |

Part Name |

Material |

||

|

GB |

ASTM |

GB |

ASTM |

||||

|

1 |

Jacket |

25 |

A105 |

5 |

Sphere |

|

|

|

2 |

Valve seat |

WCB |

A216-WCB |

6 |

Stem |

1Cr13 |

A247-410 |

|

3 |

Valve body |

1Cr18Ni9Ti |

SS304 |

7 |

Packing |

flexible graphite |

|

|

4 |

Sealing ring |

PTFE, para-polystyrene |

8 |

Packing gland |

WCB |

A216-WCB |

|

Technical Specifications

|

Design Criteria |

ASMEB16.34GB/T12224 |

|

Structure length |

ASMEB16.10GB/T12221 |

|

Connecting flange |

ASMEB16.34JB/T79 |

|

Drive mode |

Manual, electric, pneumatic |

|

TEST AND INSPECTION |

JB/T9092 API 598 |

|

Applicable media |

Heavy oil, glue and other easy solidification medium |

|

Nominal diameter DN |

L |

D |

D1 |

D2 |

B |

F |

Z-Φd |

2-G |

|

15 |

130 |

95 |

65 |

45 |

14 |

2 |

4-Φ14 |

3/8 |

|

20 |

150 |

105 |

75 |

55 |

14 |

2 |

4-Φ14 |

3/8 |

|

25 |

160 |

115 |

85 |

65 |

14 |

2 |

4-Φ14 |

3/8 |

|

32 |

165 |

135 |

100 |

78 |

16 |

2 |

4-Φ18 |

1/2 |

|

40 |

180 |

145 |

110 |

85 |

16 |

3 |

4-Φ18 |

1/2 |

|

50 |

200 |

160 |

125 |

100 |

16 |

3 |

4-Φ18 |

1/2 |

|

65 |

220 |

180 |

145 |

120 |

18 |

3 |

4-Φ18 |

1/2 |

|

80 |

250 |

195 |

160 |

135 |

20 |

3 |

4-Φ18 |

1/2 |

|

100 |

280 |

215 |

180 |

155 |

20 |

3 |

4-Φ18 |

1/2 |

|

125 |

320 |

280 |

240 |

210 |

22 |

3 |

4-Φ23 |

1/2 |

|

150 |

360 |

335 |

295 |

265 |

26 |

3 |

4-Φ23 |

1/2 |

Products Message

We will contact you within one working day. Please pay attention to your email.