Electric knife gate valve

Keywords:

Included in the category:

Product Description

1. The electric gate valve can be installed in the horizontal pipeline or vertical pipeline, single and double gate valve should be installed in the horizontal pipeline, and the hand wheel should be located above the valve, not allowed to install down. Gate valve medium flow direction is not limited.

2. Electric gate valve usually adopts flange connection, special occasions also useful welding connection.

3. For large diameter and high pressure gate valve, opening and closing torque is larger. In order to reduce the opening and closing torque, the bypass valve can be installed. The bypass valve is installed outside the main gate valve, and its inlet and outlet are connected to the two sides of the main gate valve and connected in parallel. The bypass valve should be opened before the main gate valve is opened. After entering the valve, the pressure difference before and after the main gate valve gate is reduced, thereby reducing the opening torque of the main gate valve. The selection of bypass valve caliber should be considered according to the main valve caliber and use requirements.

4. The electric gate valve is a cut-off valve, and its sealing performance is not as good as that of the cut-off valve. The main "duty" of the gate valve is to "cut off the flow", as well as to zui small resistance: "freewheeling". It should not be used to adjust the flow and pressure of the medium, such as * for adjustment, the sealing surface is easy to be washed and worn by the medium, affecting the sealing performance.

5. Electric gate valve medium temperature, pressure, the reliability of the use should be paid attention. At high temperature and high pressure, the gate may die due to temperature changes, and the non-sealing phenomenon is easy to occur due to uneven temperature of the medium. Wedge type but the gate valve is particularly obvious.

6. The initial power should pay attention to the phase sequence of the power supply, the correct operation method is to manually open the gate valve to the middle position, and then inching operation switch valve, the valve stroke adjustment (specific adjustment method manufacturer), can be normal operation.

The soft seal knife gate valve is a common seal in the knife gate valve seal. The sealing material is generally ordinary rubber, nitrile rubber or silicone rubber. Its series of products are widely used in various industrial fields, especially in mining, iron and steel industry-for coal, filter slurry, purification device-for waste water, slurry, dirt and clarified water with suspended solids, paper industry-for any concentration pulp, material water mixture, power station ash removal-for ash slurry and other professional pipeline systems.

Features of soft sealing knife gate valve

1. Simple structure, beautiful appearance, full passage channel and small flow resistance coefficient. When the ram is lifted, the adhesive on the sealing surface is scraped off at the same time, and the debris is automatically removed.

2. Stainless steel gate can prevent seal leakage caused by corrosion. The overall stainless steel material prevents corrosion damage and has a long service life.

3. The soft sealing knife gate valve can also be driven by manual, worm gear, electric, pneumatic, hydraulic and other driving methods to meet the different needs of users.

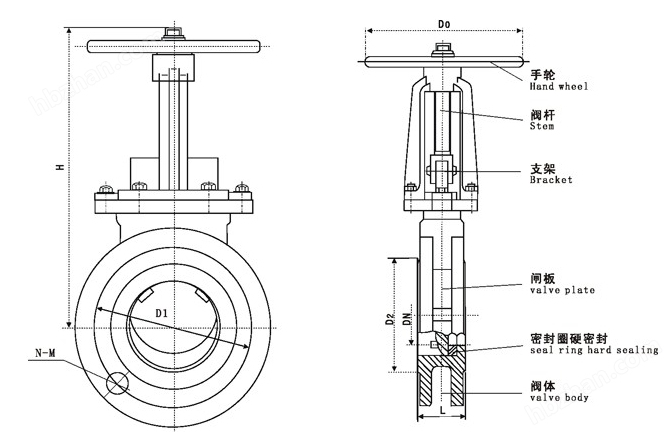

Nominal pressure | Nominal diameter (mm) | L | D | D1 | D2 | N-M | D0 |

1.0 | 50 | 48 | 160 | 125 | 100 | 4-M16 | 180 |

65 | 48 | 180 | 145 | 120 | 4-M16 | 180 | |

80 | 50 | 195 | 160 | 135 | 4-M16 | 220 | |

100 | 50 | 215 | 180 | 155 | 8-M16 | 220 | |

125 | 57 | 245 | 210 | 185 | 8-M16 | 230 | |

150 | 57 | 280 | 240 | 210 | 8-M20 | 280 | |

200 | 70 | 335 | 295 | 265 | 8-M20 | 360 | |

250 | 70 | 390 | 350 | 320 | 12-M20 | 360 | |

300 | 76 | 440 | 400 | 368 | 12-M20 | 400 | |

350 | 76 | 500 | 460 | 429 | 16-M20 | 400 | |

400 | 89 | 565 | 515 | 482 | 16-M22 | 400 | |

450 | 89 | 615 | 565 | 532 | 20-M22 | 530 | |

500 | 114 | 670 | 620 | 585 | 20-M22 | 530 | |

600 | 114 | 780 | 725 | 685 | 20-M27 | 600 | |

700 | 130 | 895 | 940 | 800 | 24-M27 | 600 | |

800 | 130 | 1010 | 950 | 905 | 24-M30 | 680 | |

900 | 140 | 1110 | 1050 | 1005 | 28-M30 | 680 |

Products Message

We will contact you within one working day. Please pay attention to your email.